Advice from the experts

Spare screws are included with each part. Occasionally, you may be instructed to keep spare or unused screws for a later stage. Keep these spares in a safe place and label them correctly.

Please make sure you don’t mix up the screws. They look quite similar, but the threads do vary slightly. Using the wrong screws may damage the parts. Only use the correct size screwdriver that fits the screw head firmly.

When securing parts together using multiple screws, fit each screw loosely to ensure all the parts are correctly aligned before gently tightening them firmly, but not overtight, in the order in which you placed them.

The screwdriver can be magnetized by stroking it with a magnet (fridge magnet, etc.) enabling it to hold the screws and make assembly easier.

If a screw is tight going into a metal part, do not force it as you may shear the head off. Remove it and put a tiny smear of Vaseline, soap or light oil on the thread. That will lubricate it and make it easier to tighten.

Some parts will require a little glue for assembly. Please apply glue sparingly and use a cocktail stick so that you don’t use too much nor apply the glue too heavily. We recommend superglue gel or Extra Thin Liquid modeling glue. Where possible, parts should be test-fitted in place before gluing.

Make sure you have good ventilation when using adhesives and to replace caps firmly.

Use a magnet to help find screws that have fallen on the floor.

Use masking tape to hold parts temporarily in place.

Cut parts from a sprue (framework) with side cutters or a craft knife. Side cutters tend to be easiest.

During the course of this build, you will receive many pieces that you will assemble immediately – following the instructions in the corresponding stage – and other pieces that you should store safely to one side, for use in future assembly stages.

Always protect the paint finish on components by placing a cutting mat, sheet of white paper or soft cloth on your work surface.

When plugging cables in, ensure the power is switched off. Tweezers can be used to fit the PVC cables by gripping carefully around 5mm from the end of the cable. If a cable needs to be removed from a socket, do not pull on the cable as this could damage the connection. Grip the plug with tweezers to remove it.

Left and Right! When building your Goldfinger DB5, the left- or right-hand side refers to that side as if you are sitting in the car.

![]() When you see this symbol, pay attention to the instruction text in bold and check the orientation of the parts in the image as this will be particularly important for assembly in later stages.

When you see this symbol, pay attention to the instruction text in bold and check the orientation of the parts in the image as this will be particularly important for assembly in later stages.

WARNING: Some parts are assembled using magnets. These magnets can cause serious injury if they are swallowed. Keep away from children. If you suspect a magnet has been swallowed, seek medical help straight away.

This is not a toy. Not suitable for children under 14 years old due to small parts. Adult supervision required.

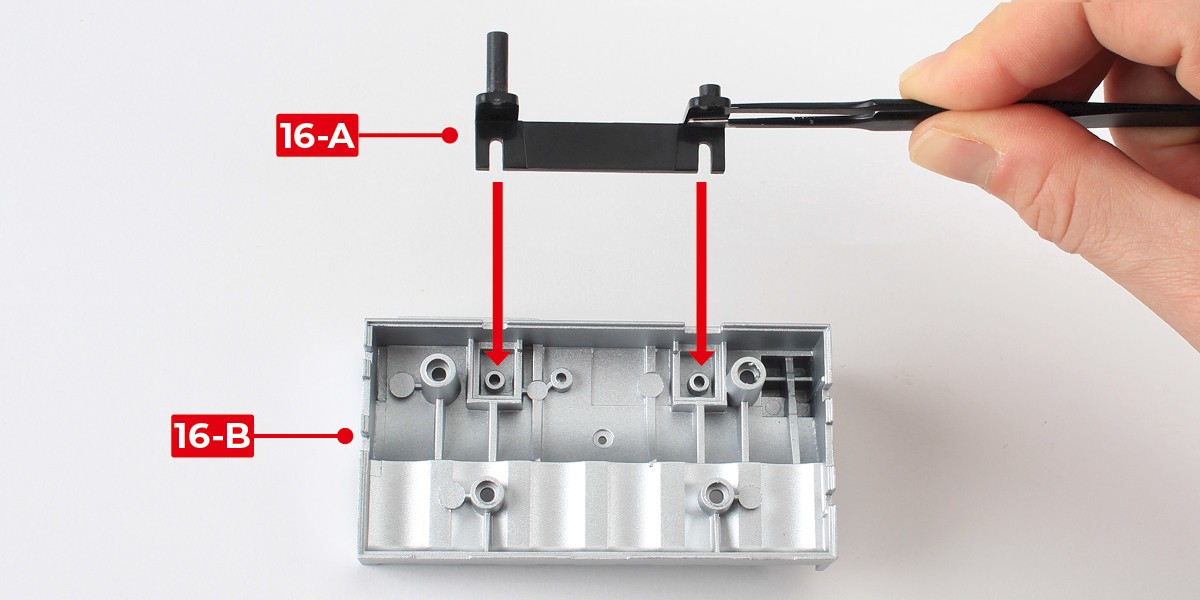

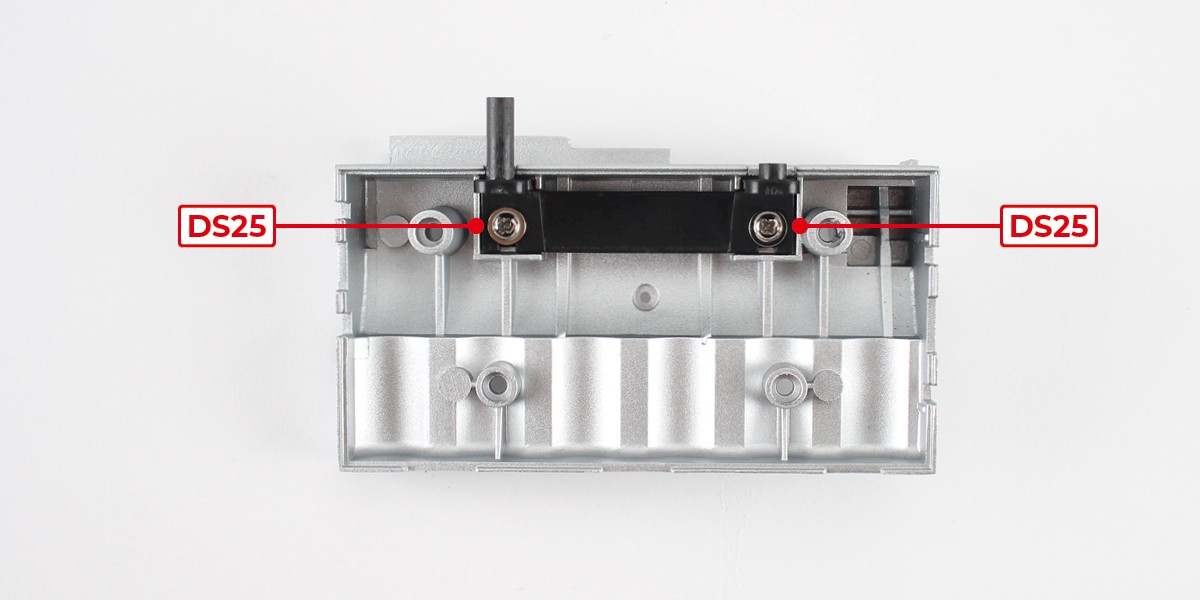

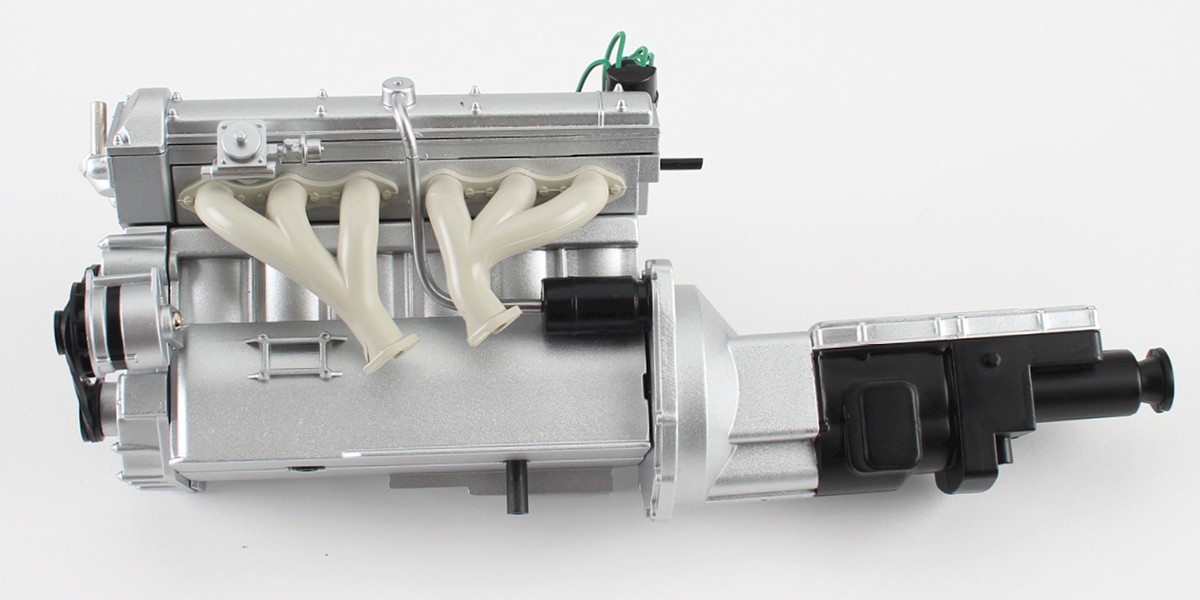

PARTS LIST

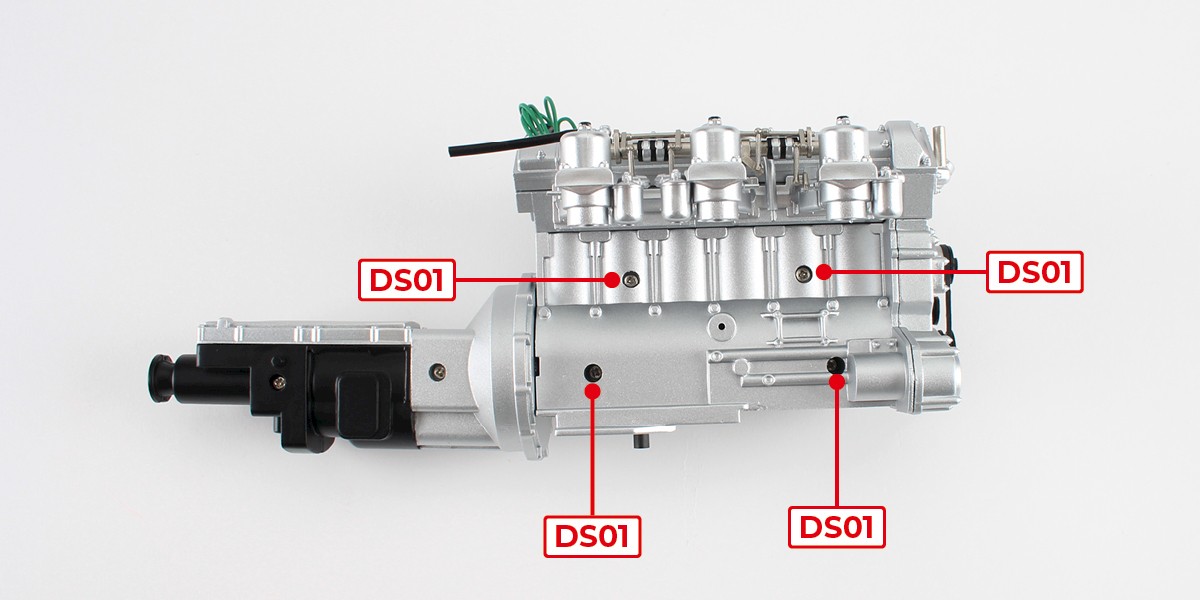

| 16-A Right engine block | 5x DS01 screws |

| 16-B Oil pan mount | 3x DS25 screws |

STAGE COMPLETE

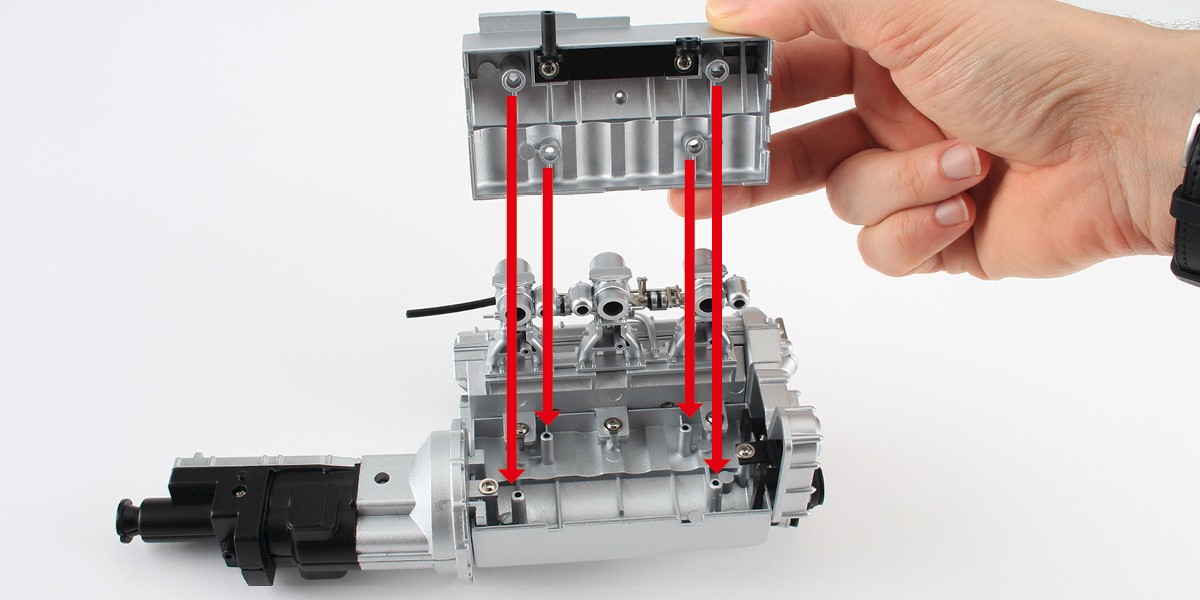

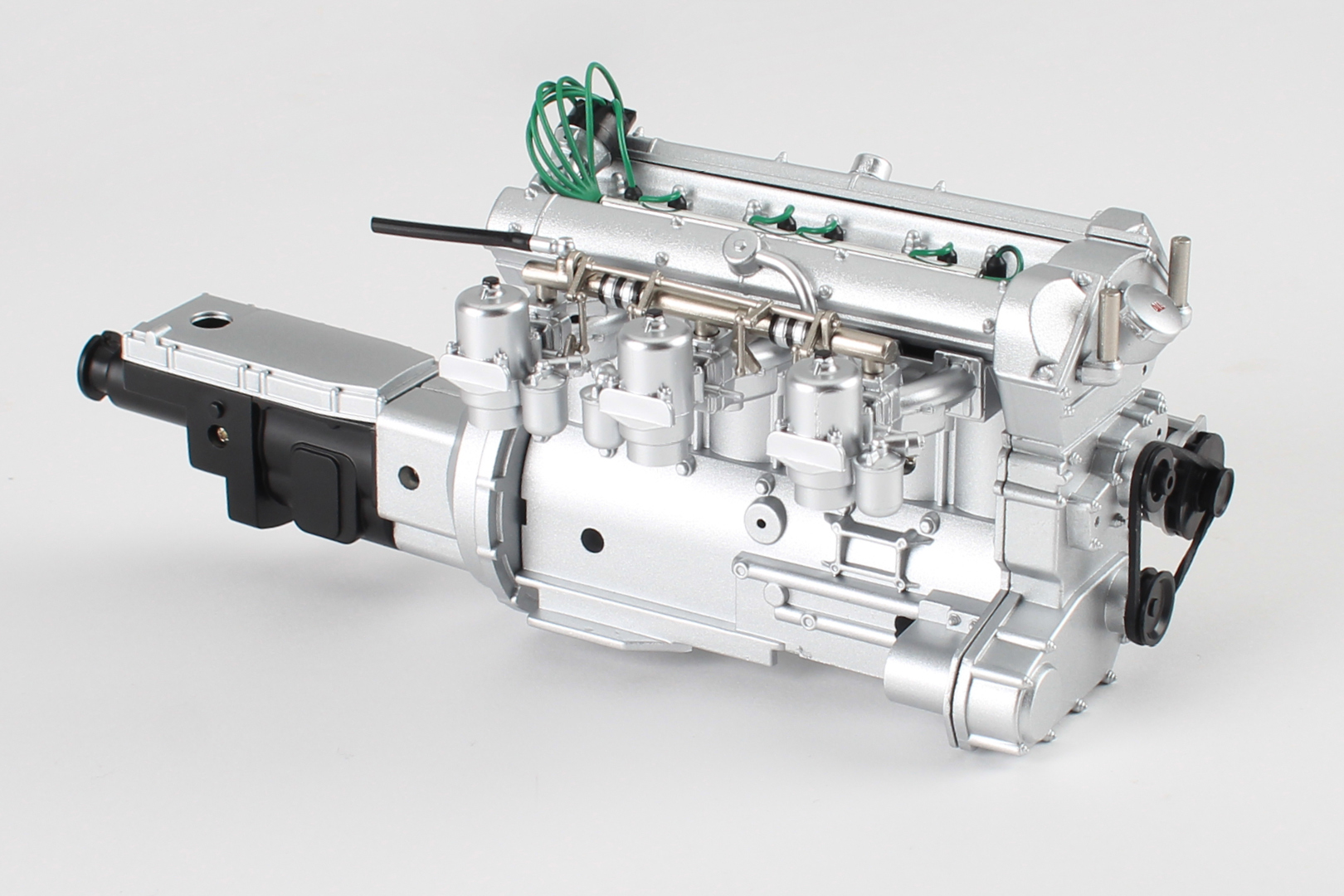

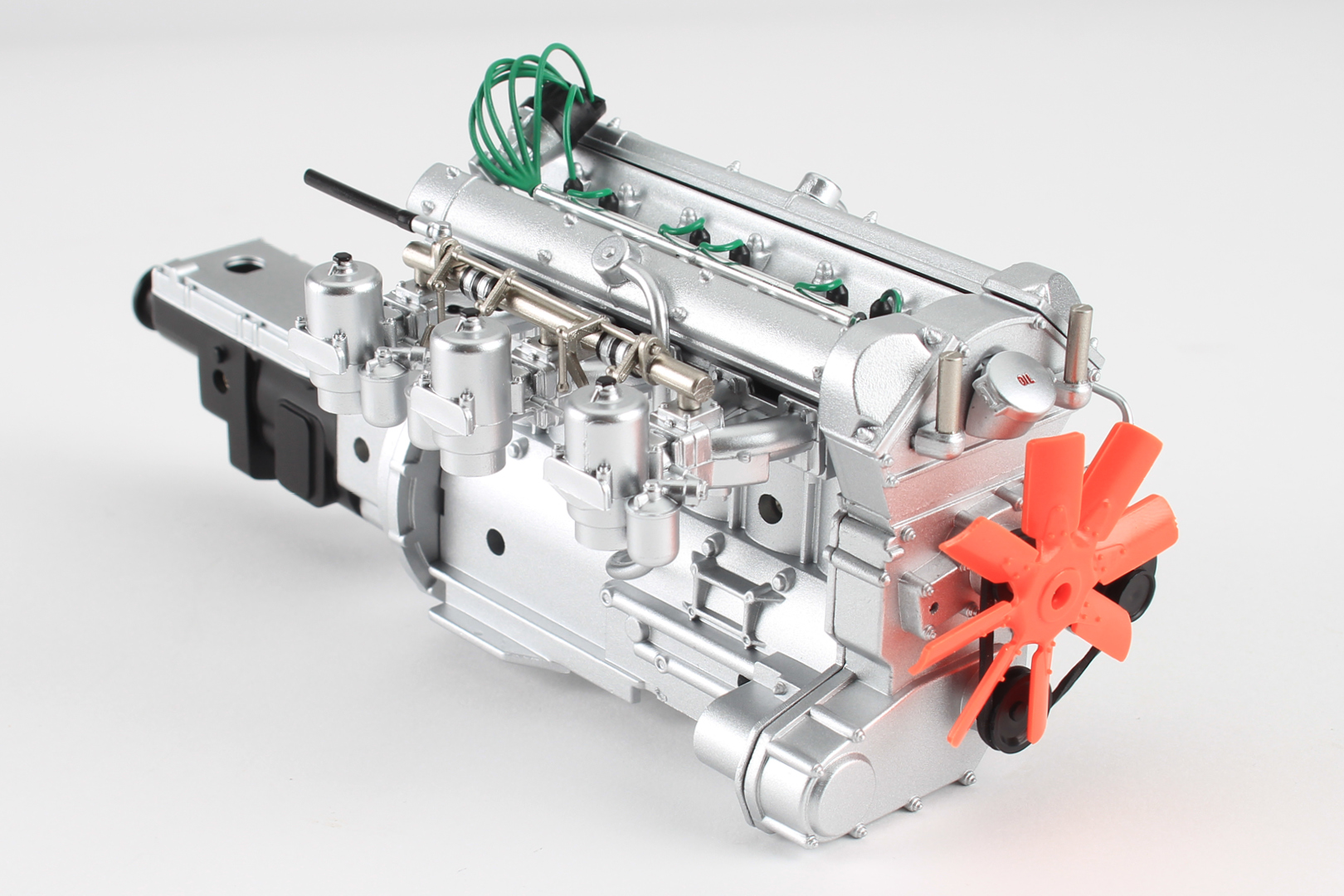

PARTS LIST

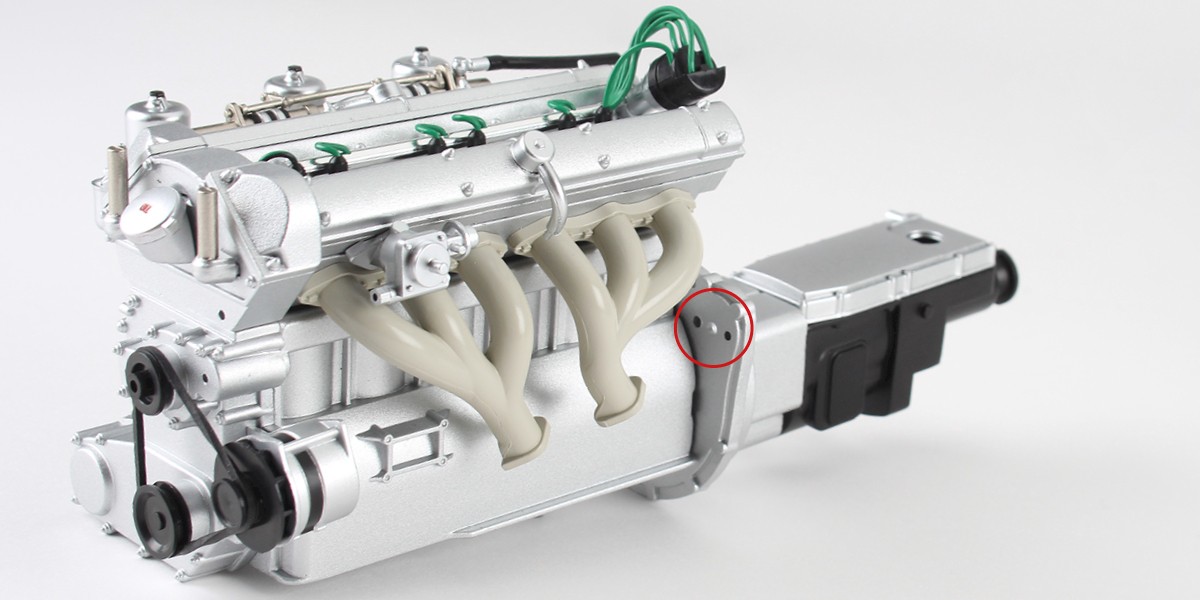

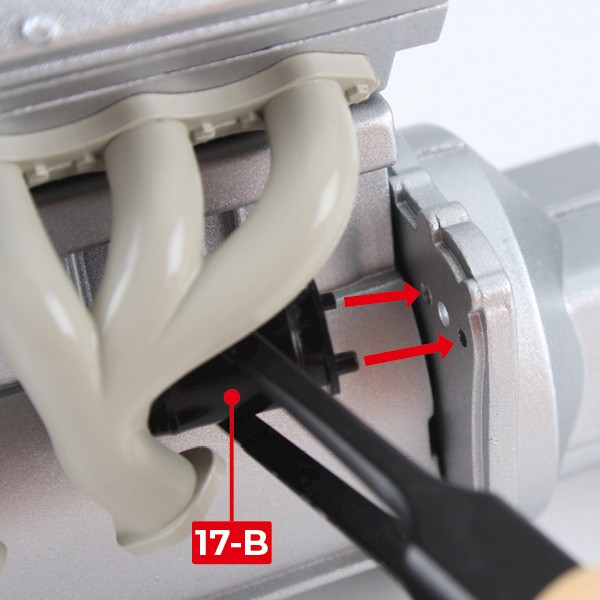

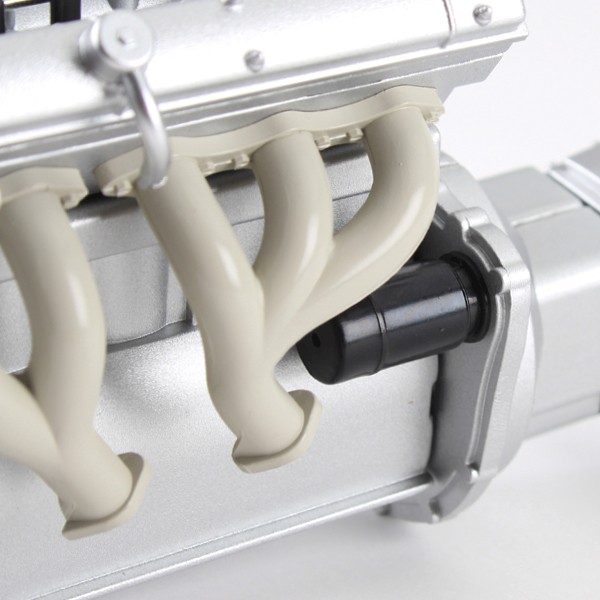

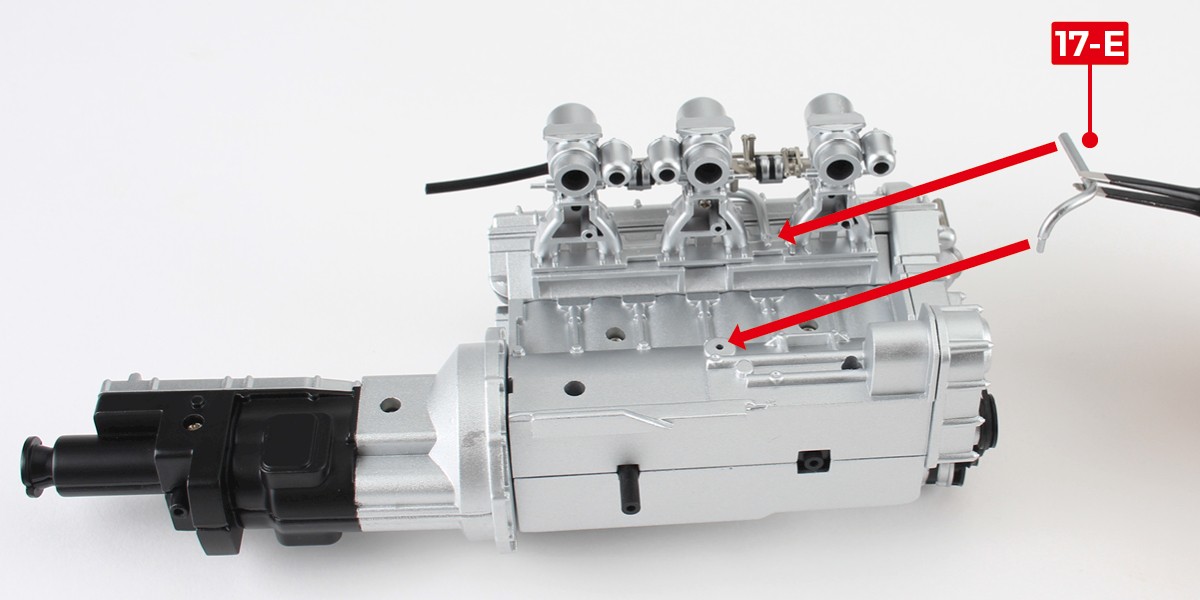

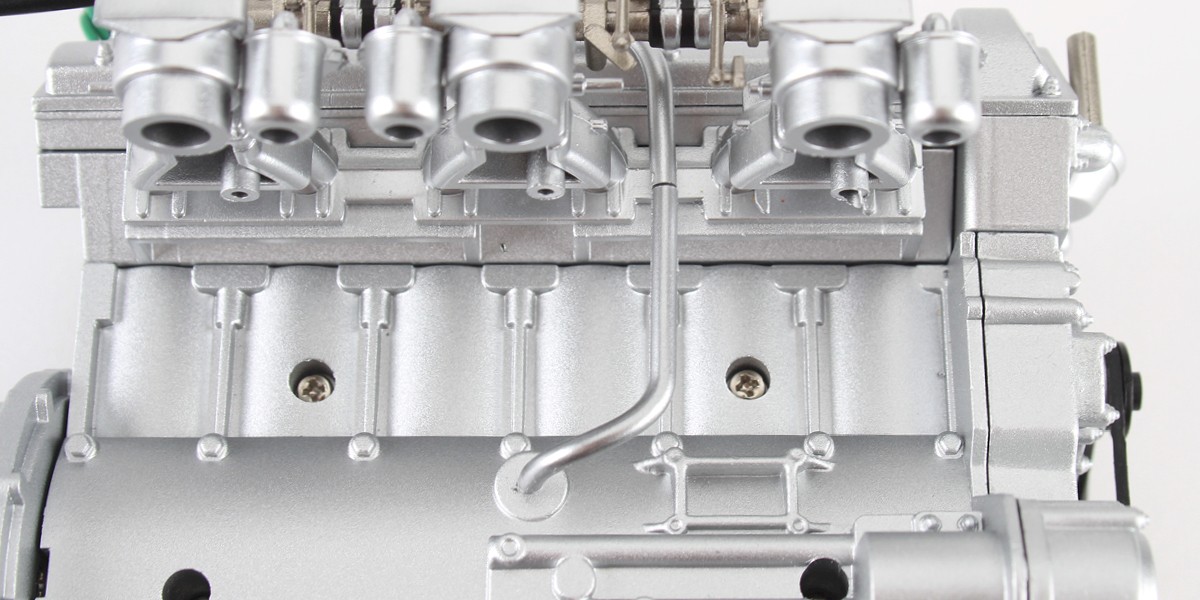

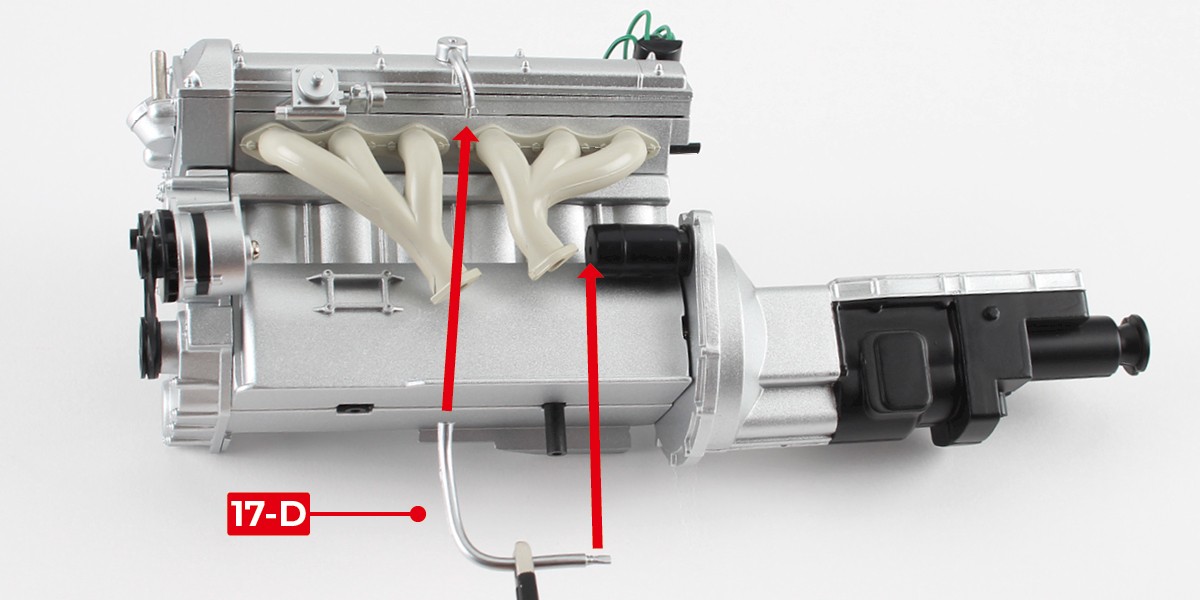

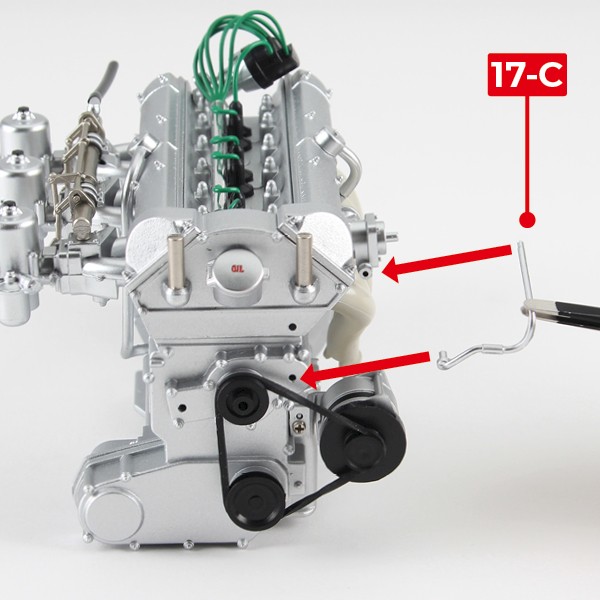

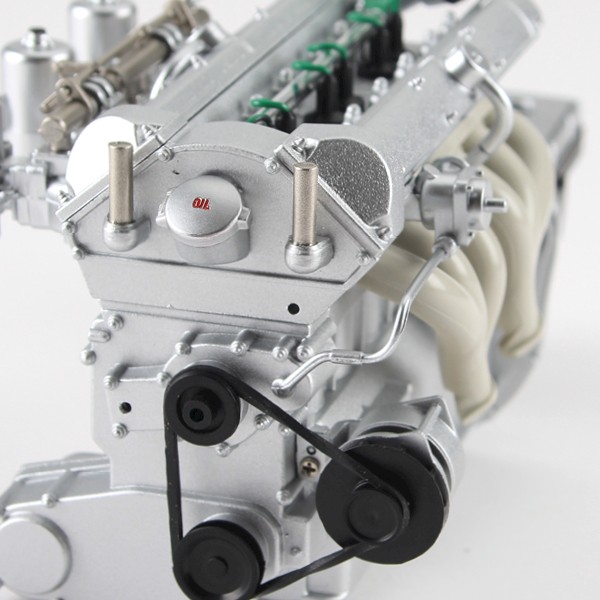

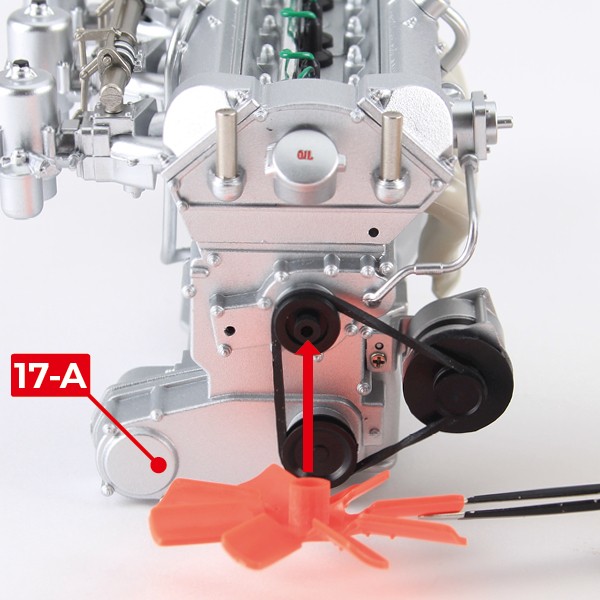

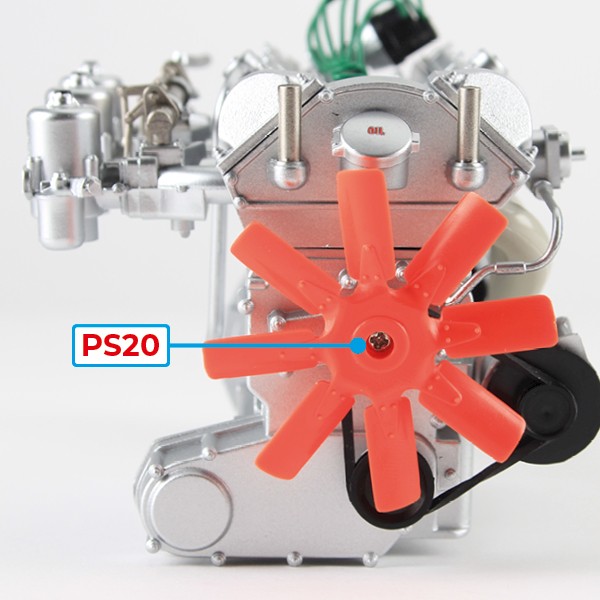

| 17-A Fan | 17-D Left breather pipe |

| 17-B Starter motor | 17-E Right breather pipe |

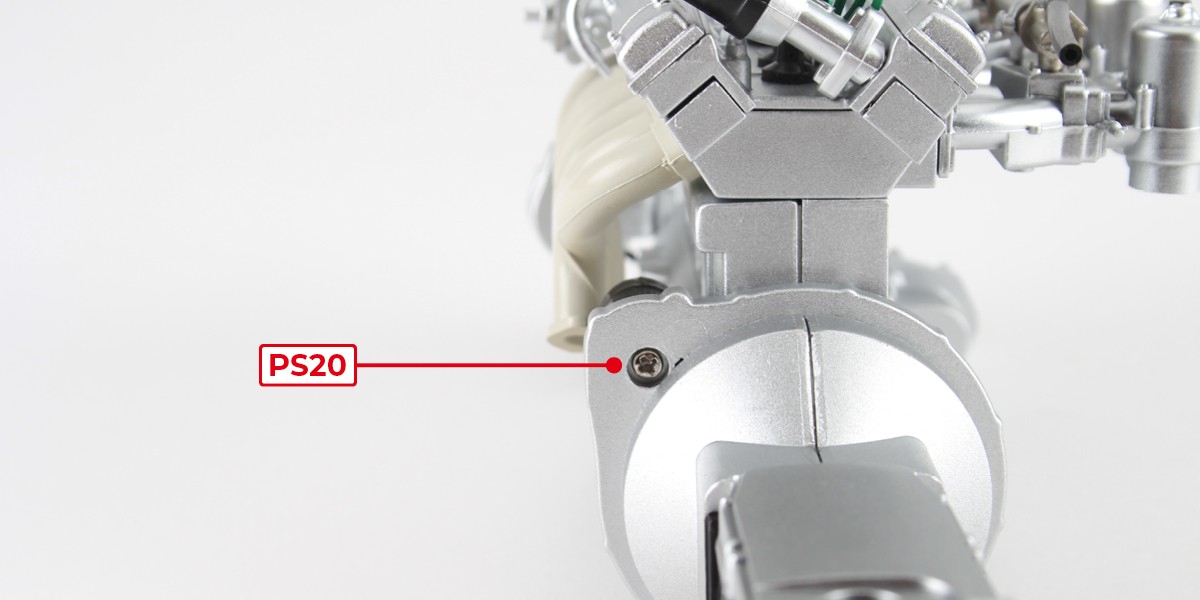

| 17-C Front water pipe | 3x PS20 screws |

STAGE COMPLETE

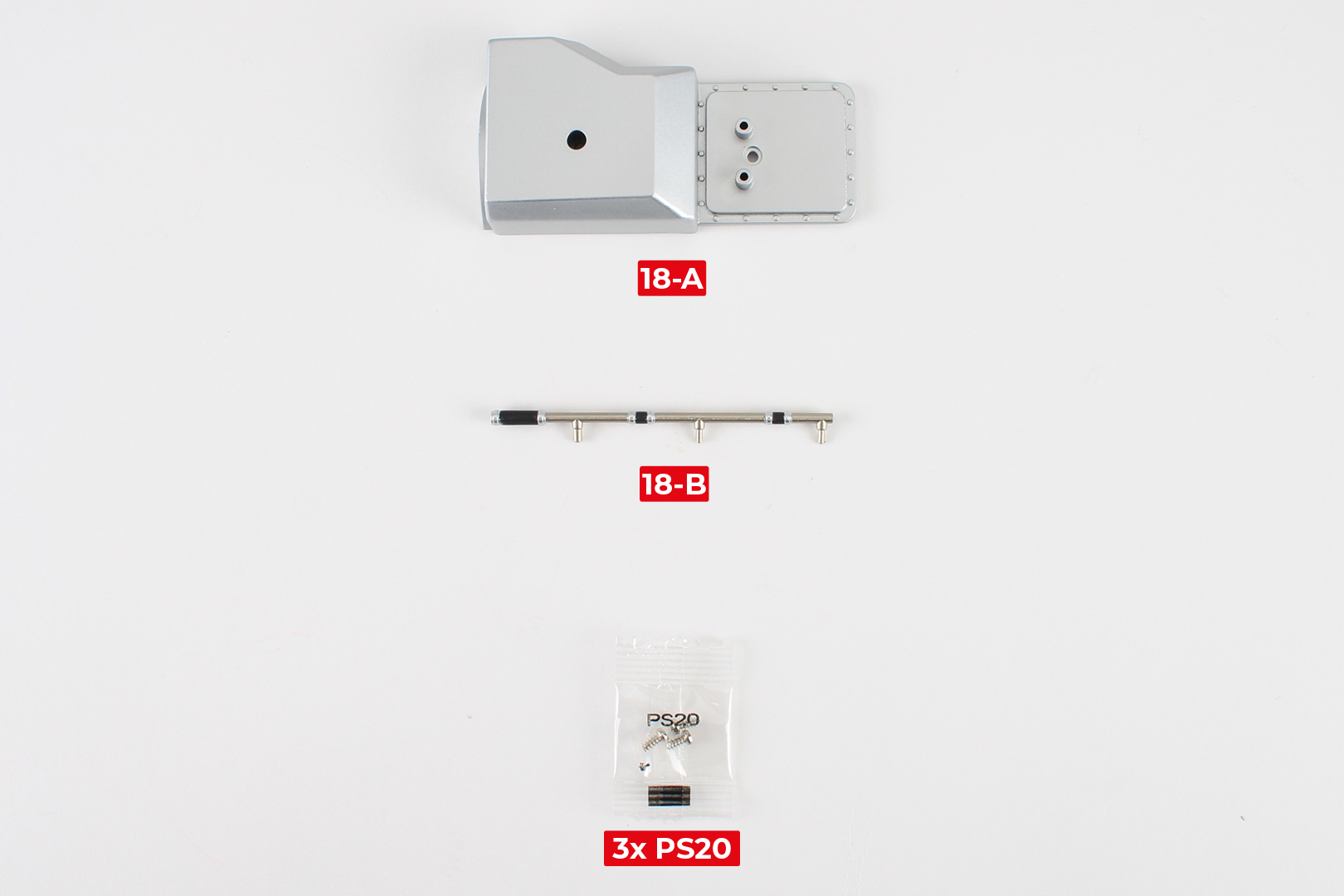

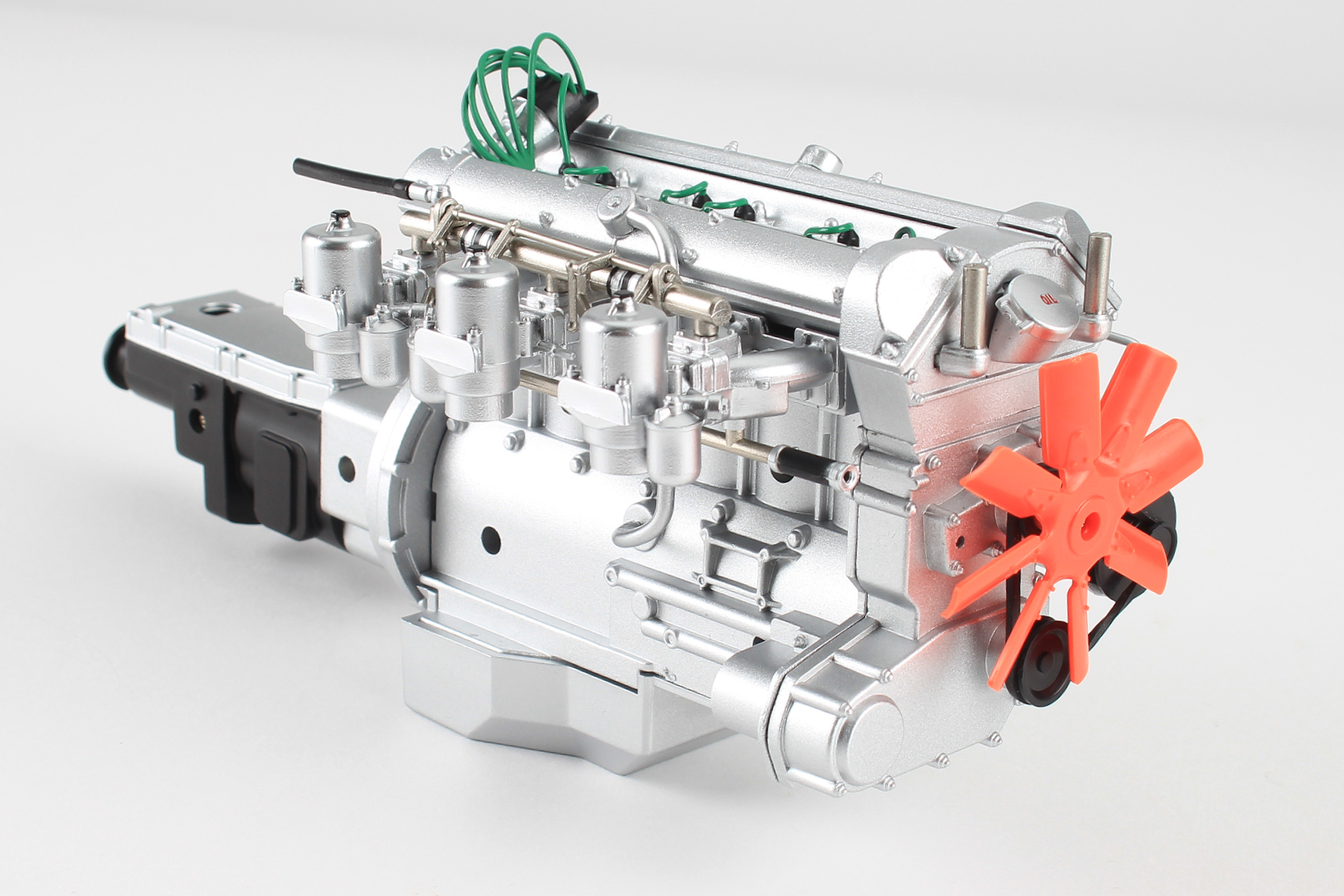

PARTS LIST

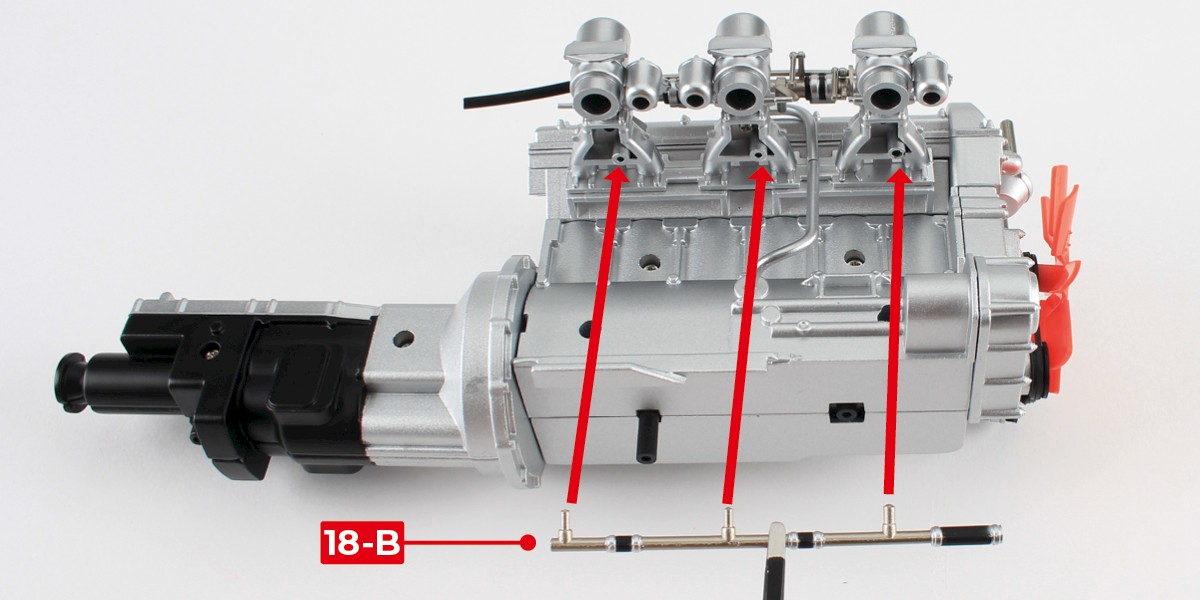

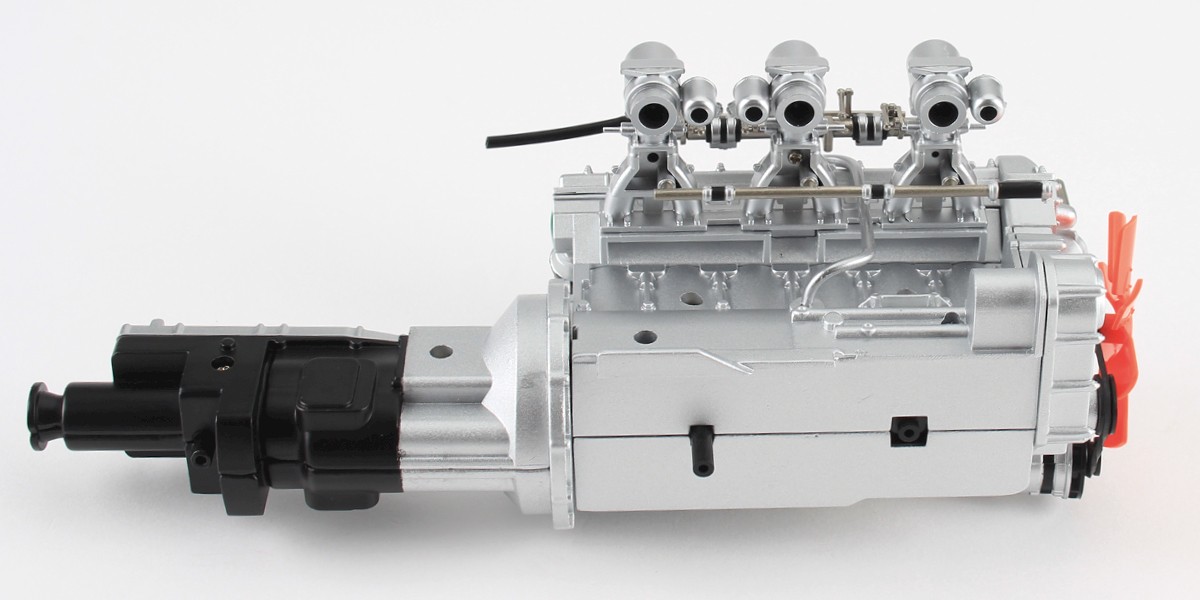

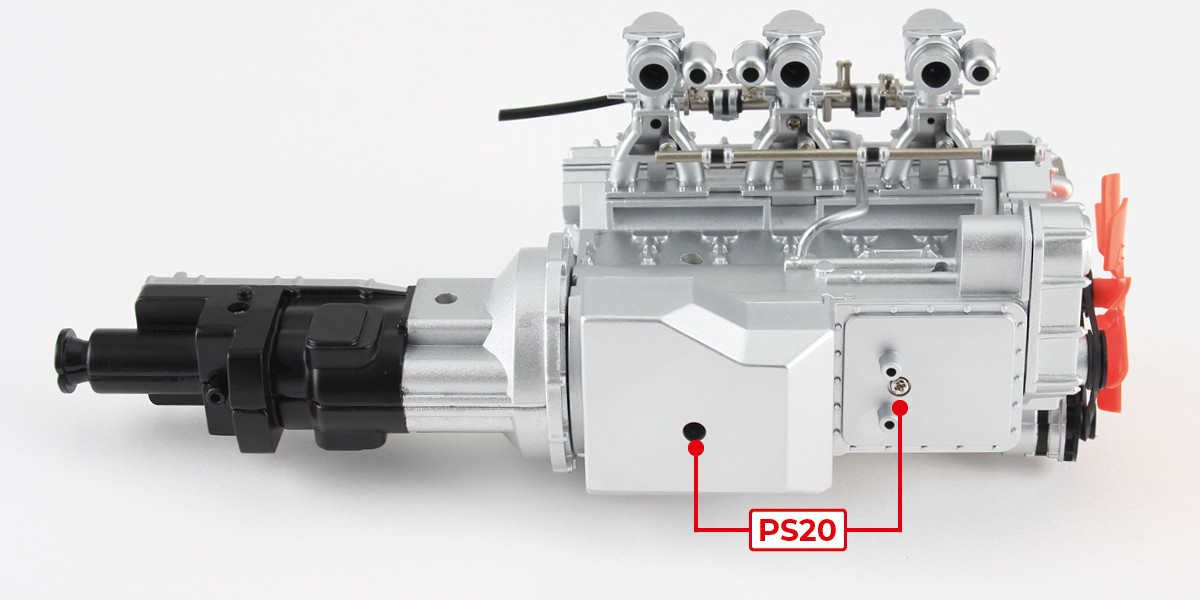

| 18-A Oil pan | 3x PS20 screws |

| 18-B Coolant pipe |

STAGE COMPLETE

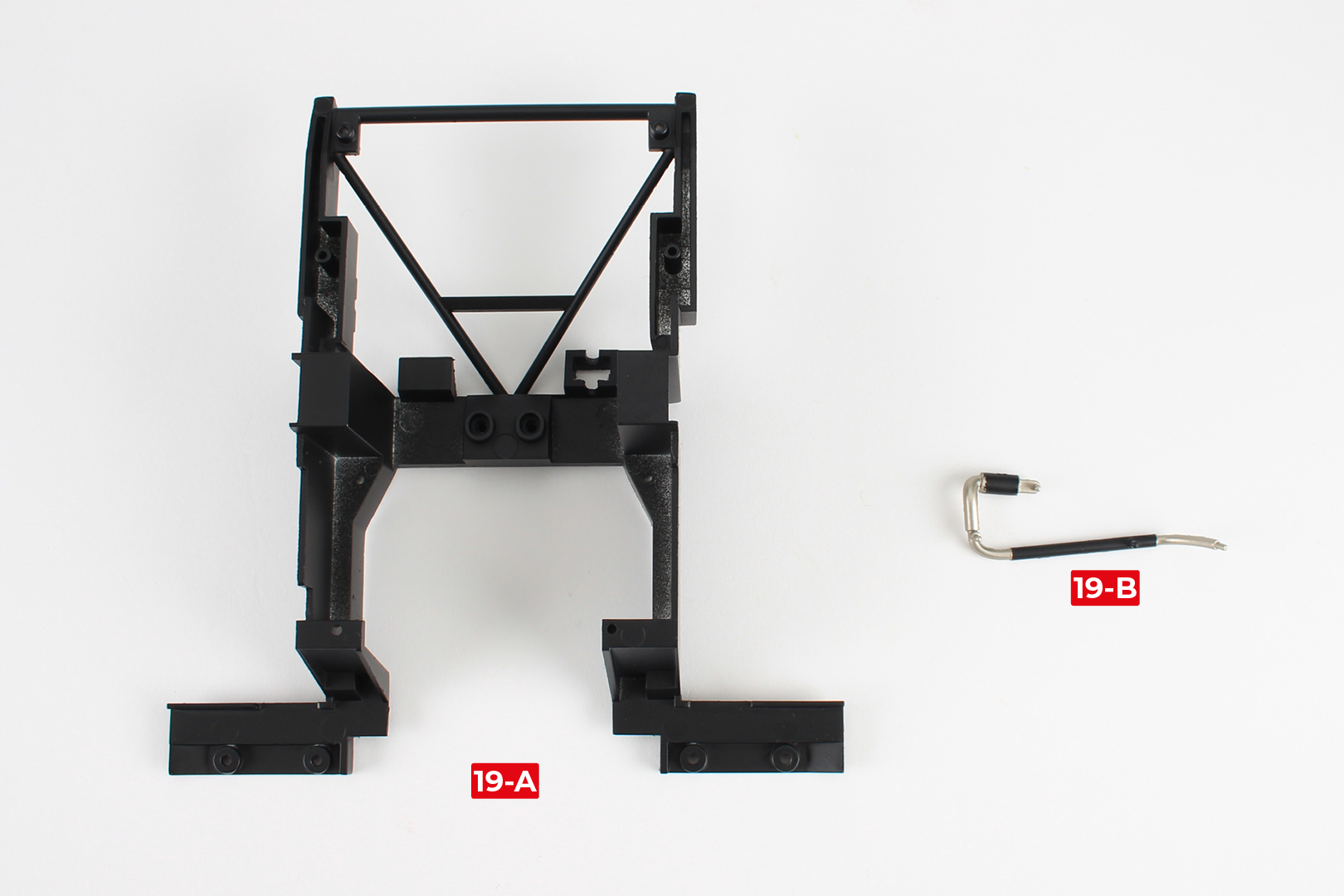

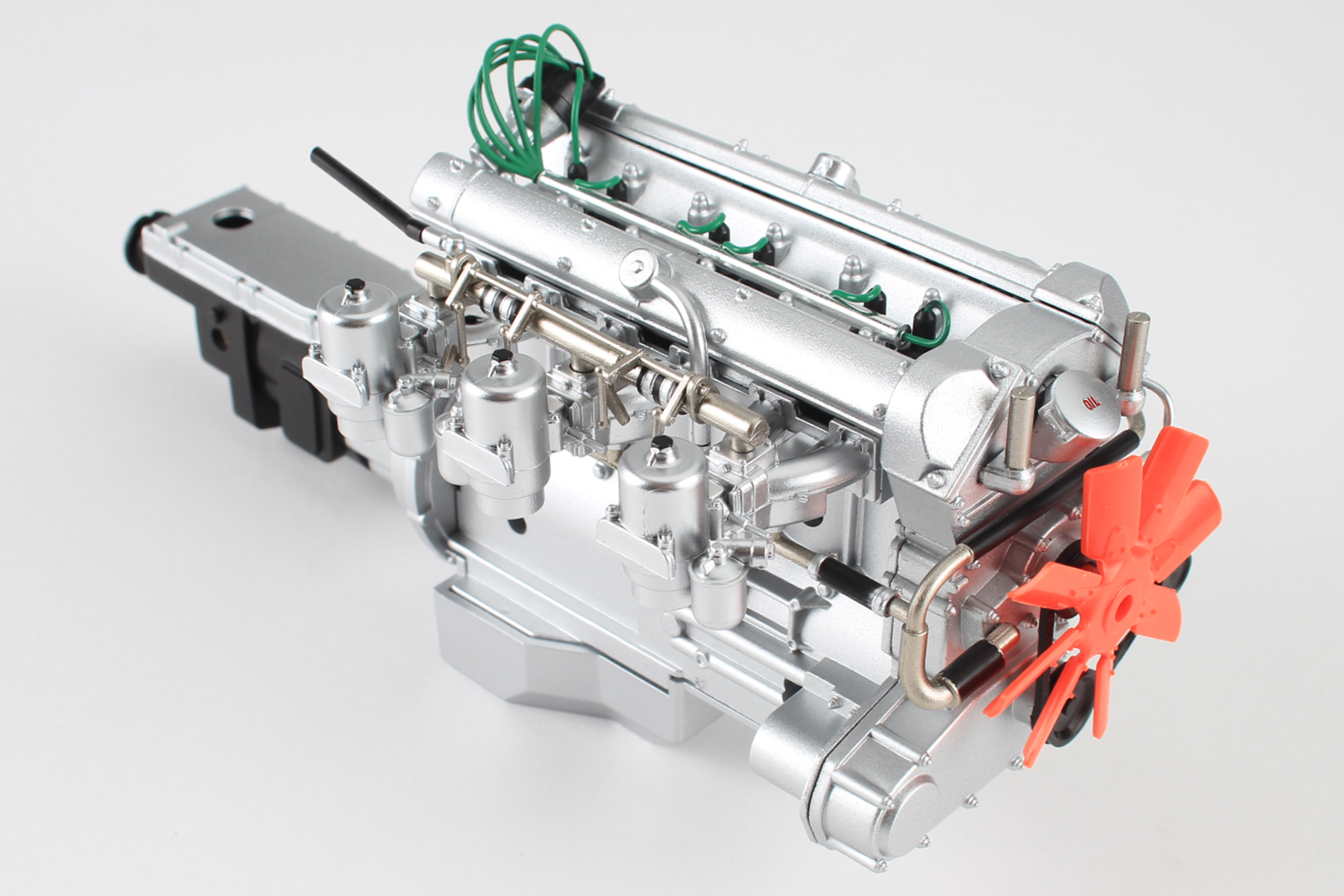

PARTS LIST

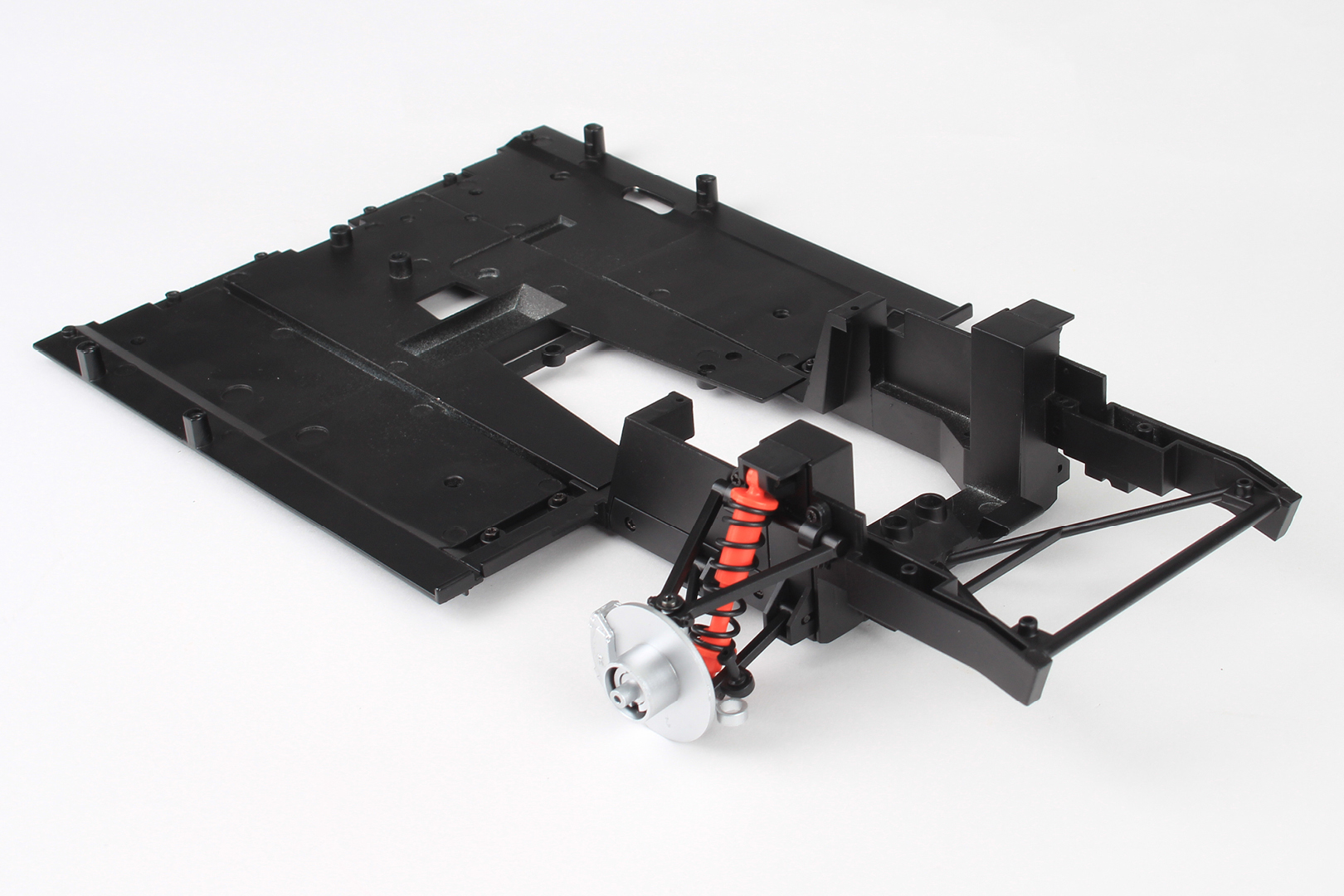

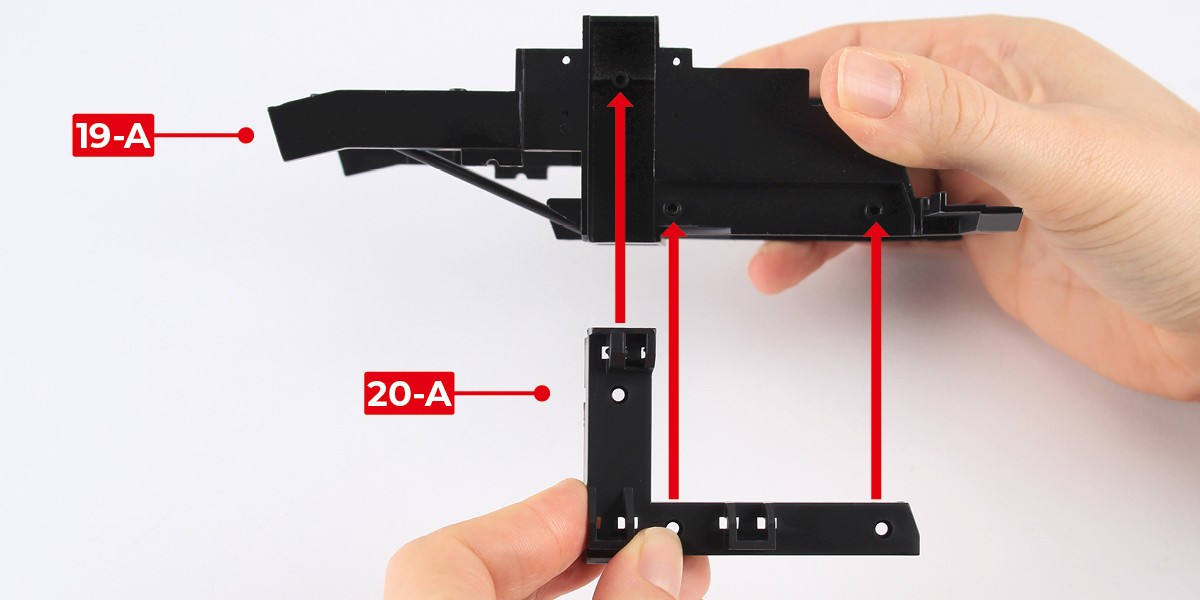

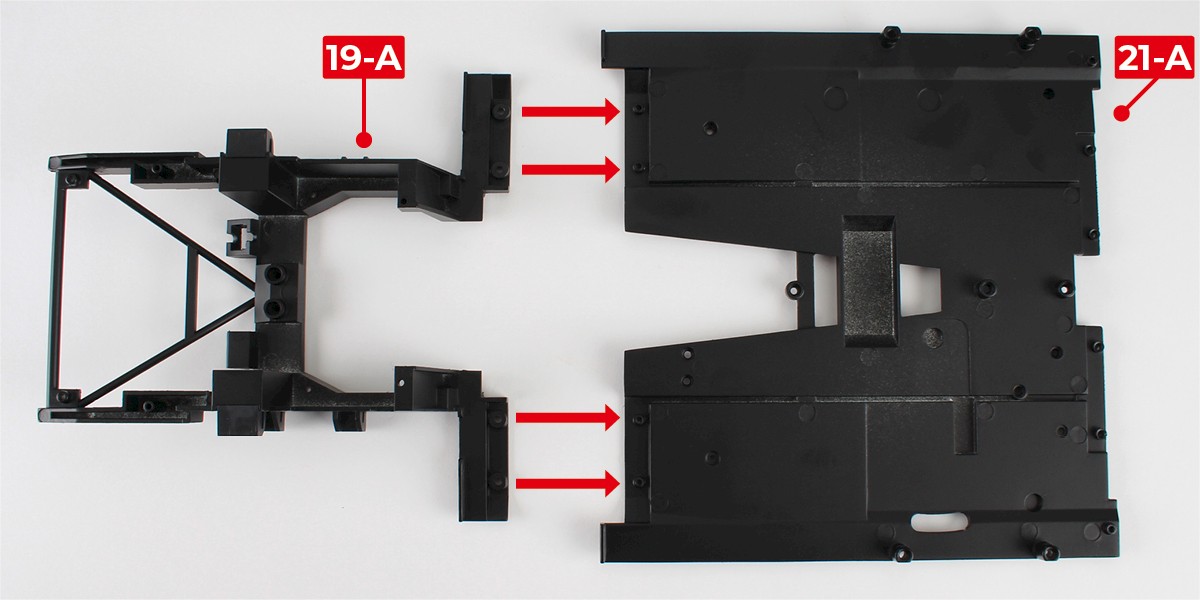

| 19-A Front section of the chassis |

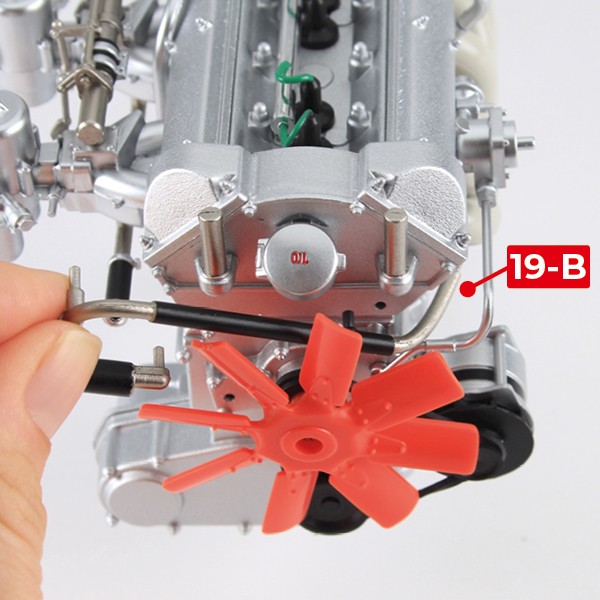

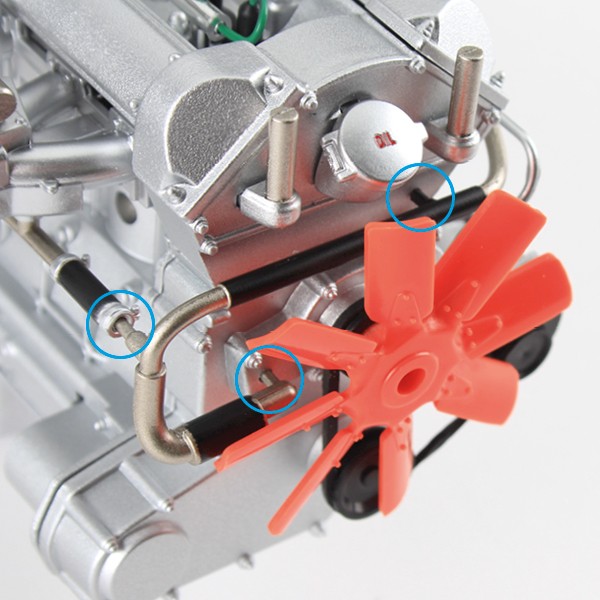

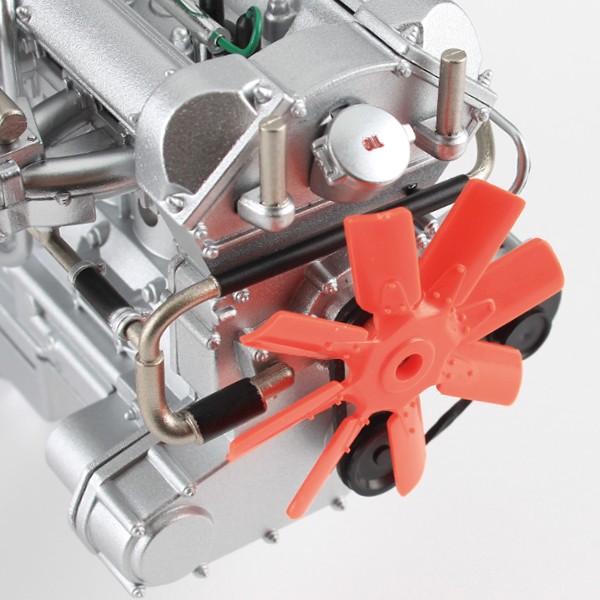

| 19-B Cooling water hose |

STAGE COMPLETE

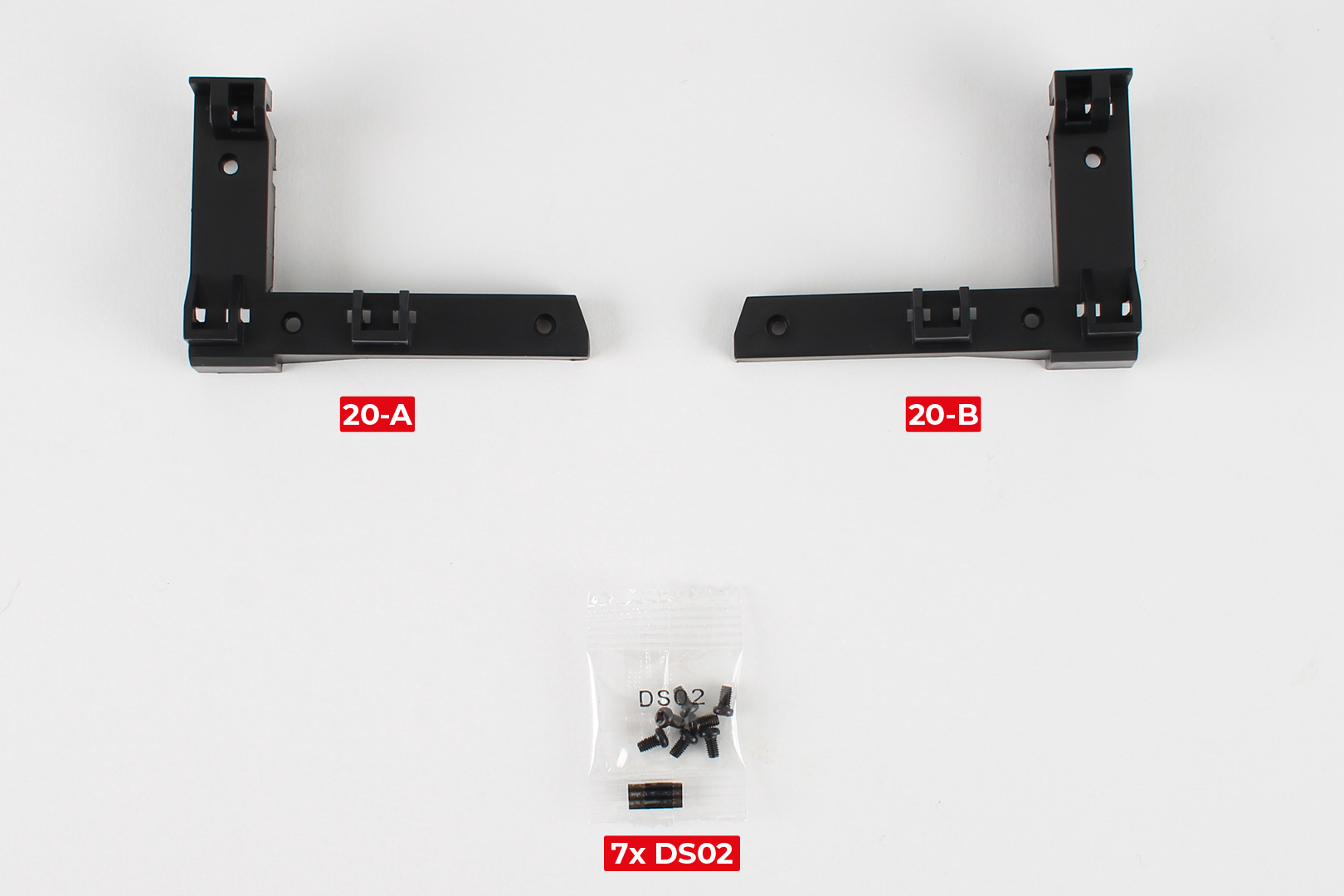

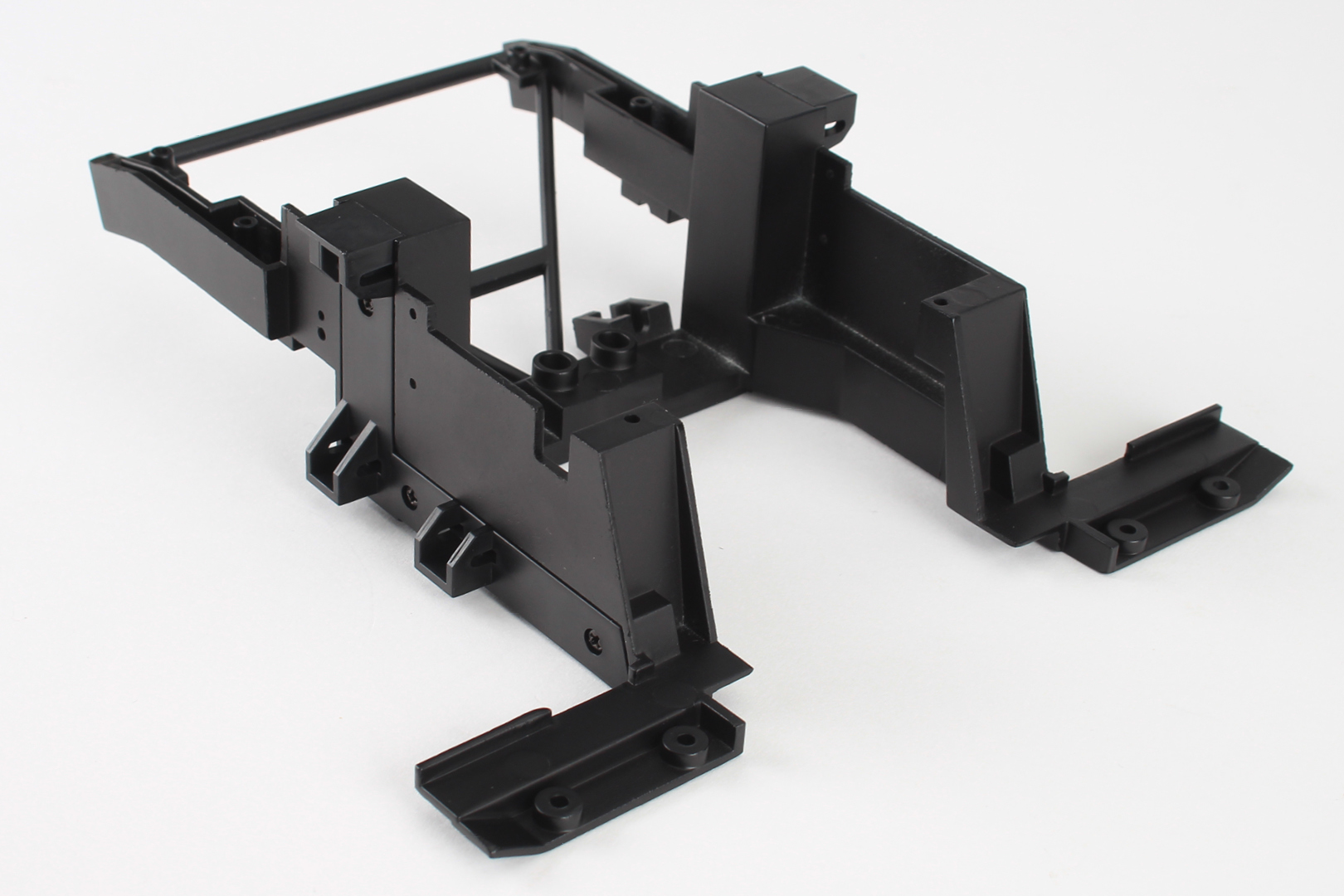

PARTS LIST

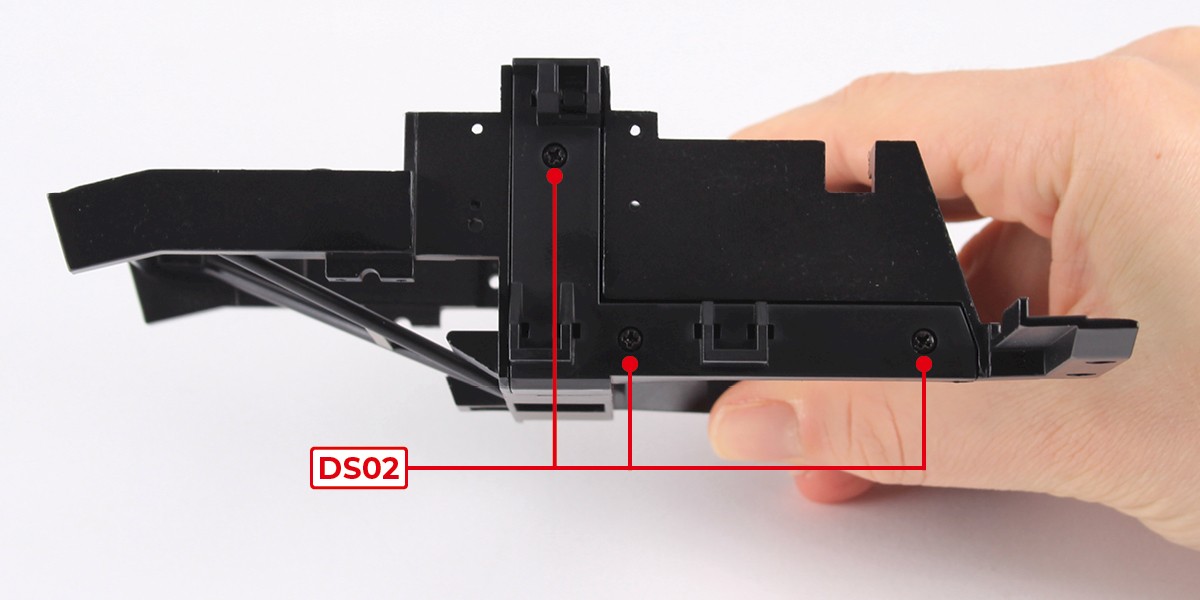

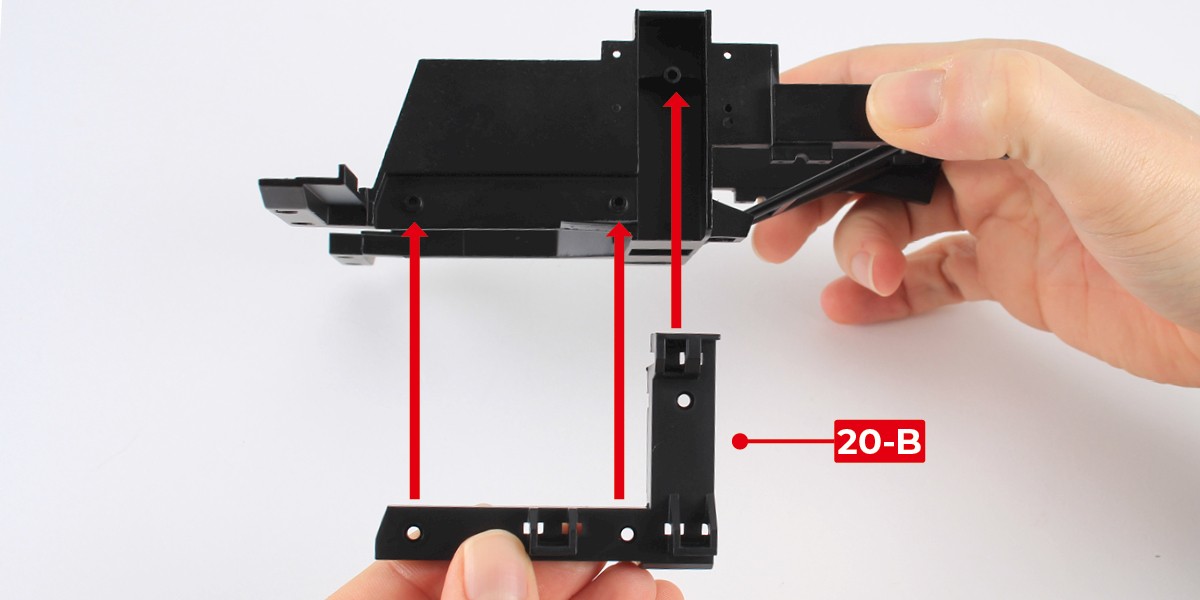

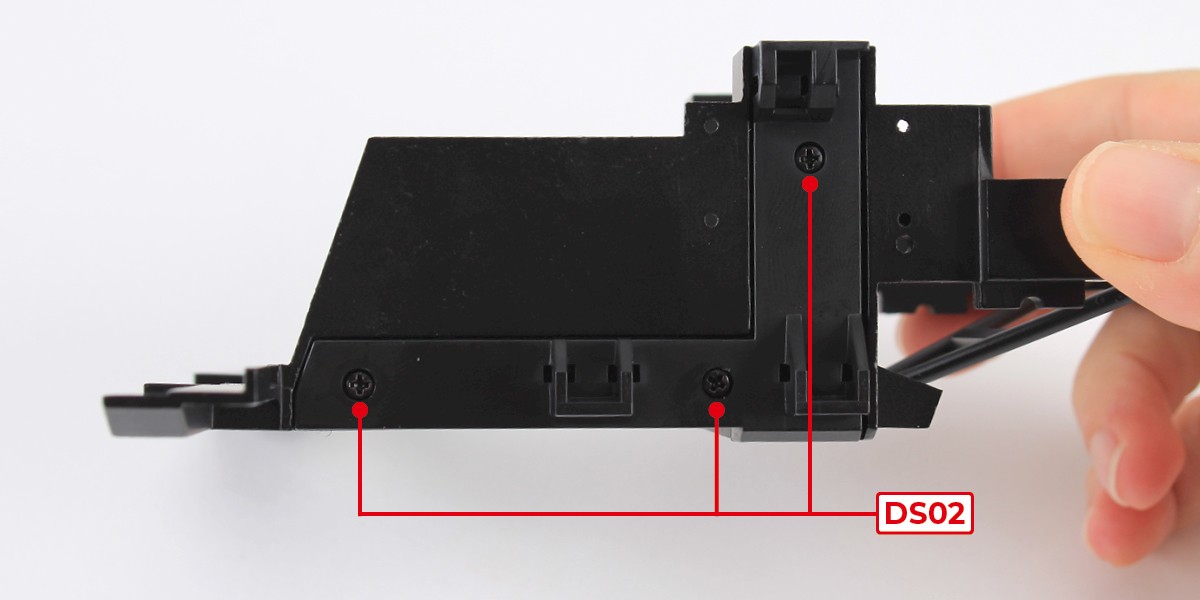

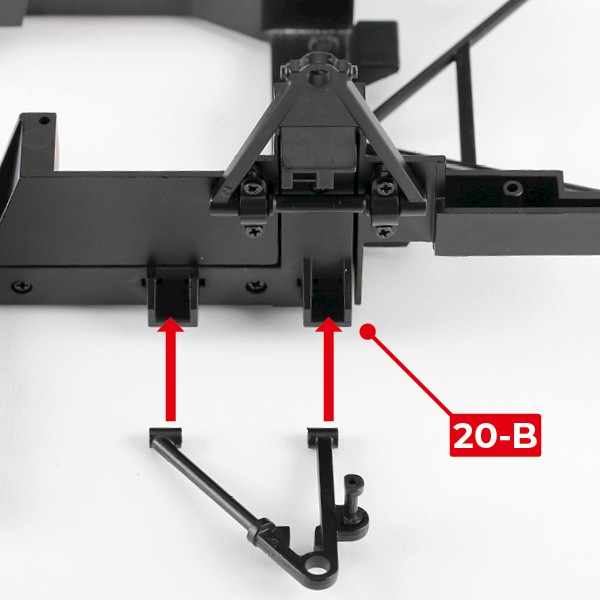

| 20-A Left suspension mount | 7x DS02 screws |

| 20-B Right suspension mount |

STAGE COMPLETE

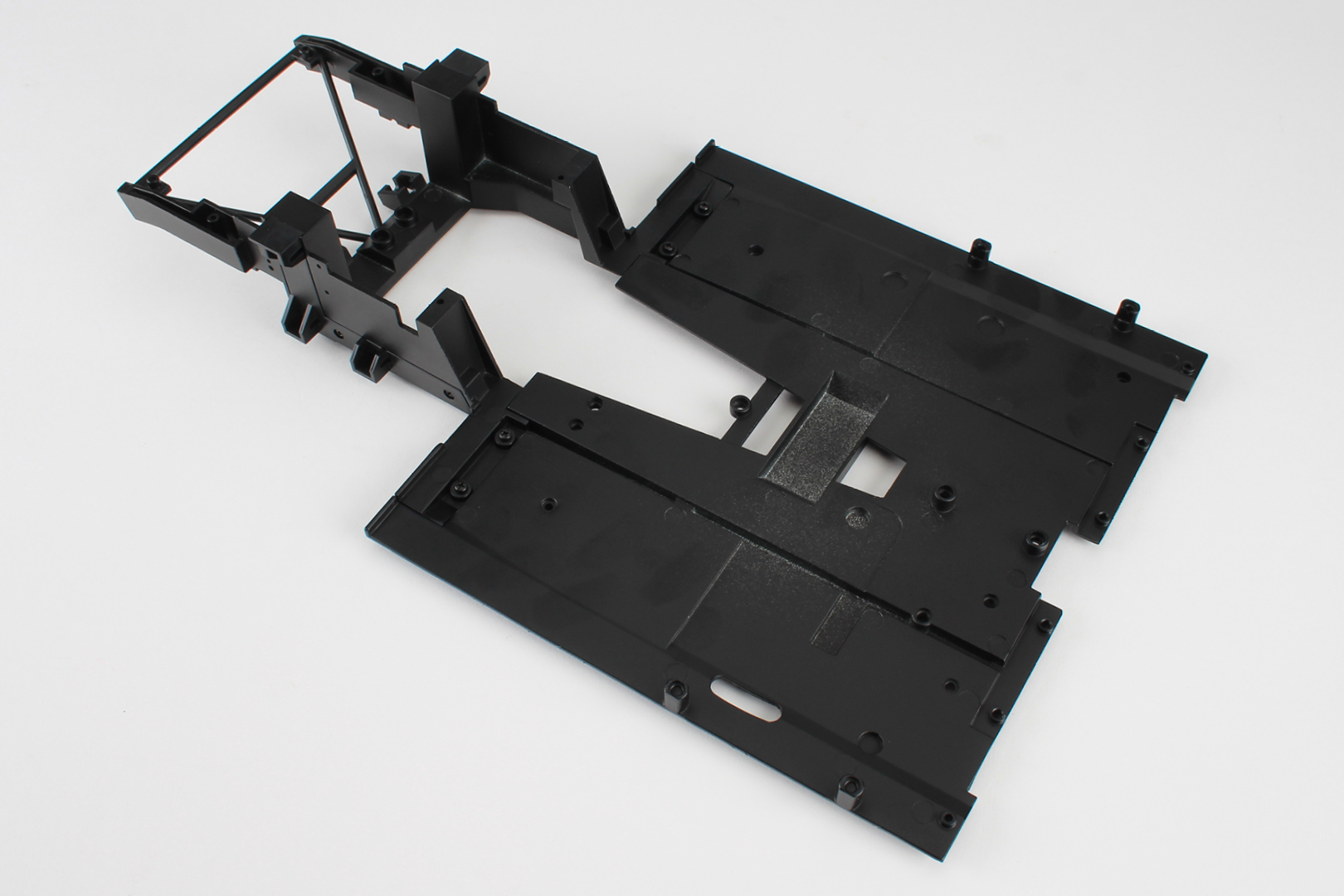

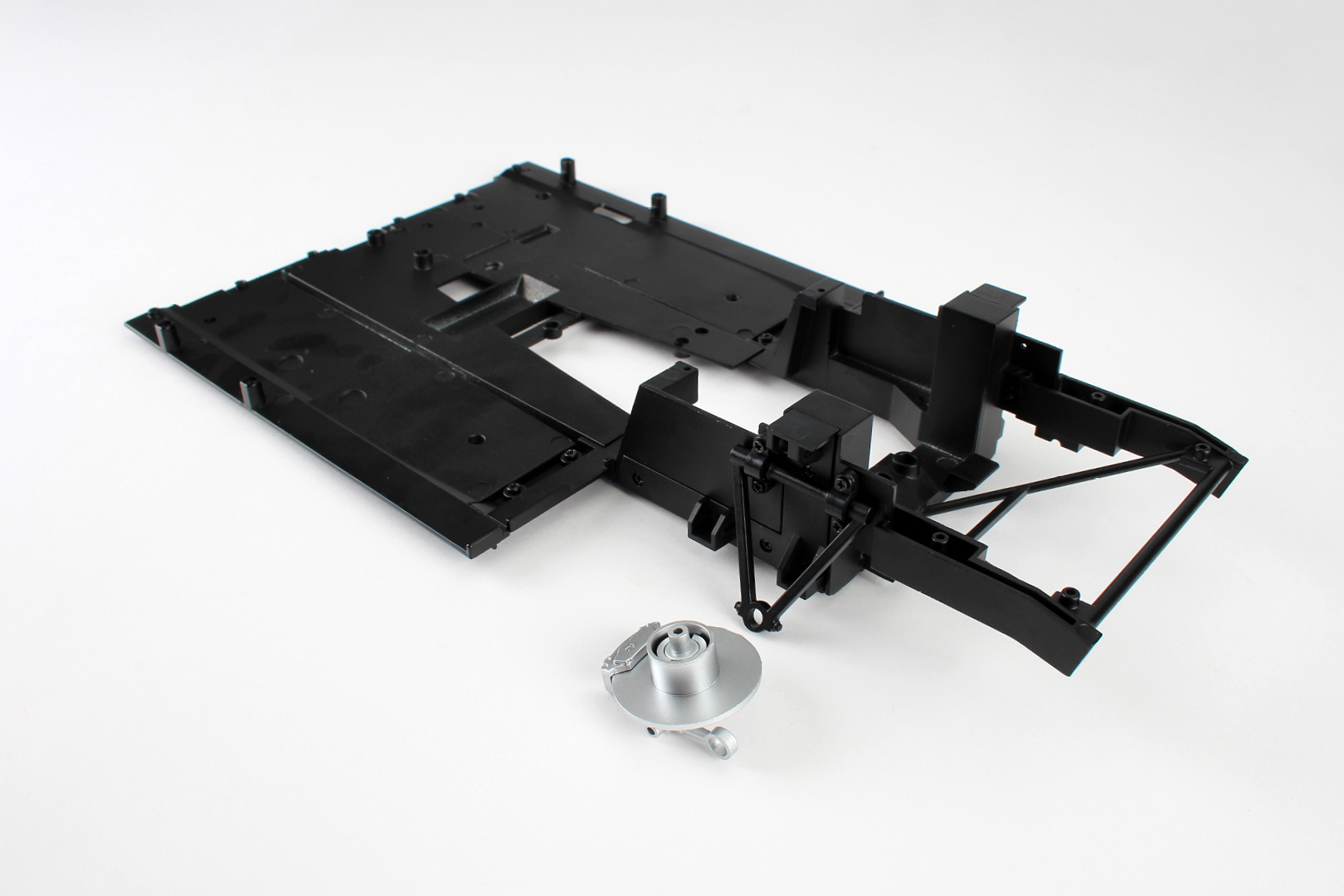

PARTS LIST

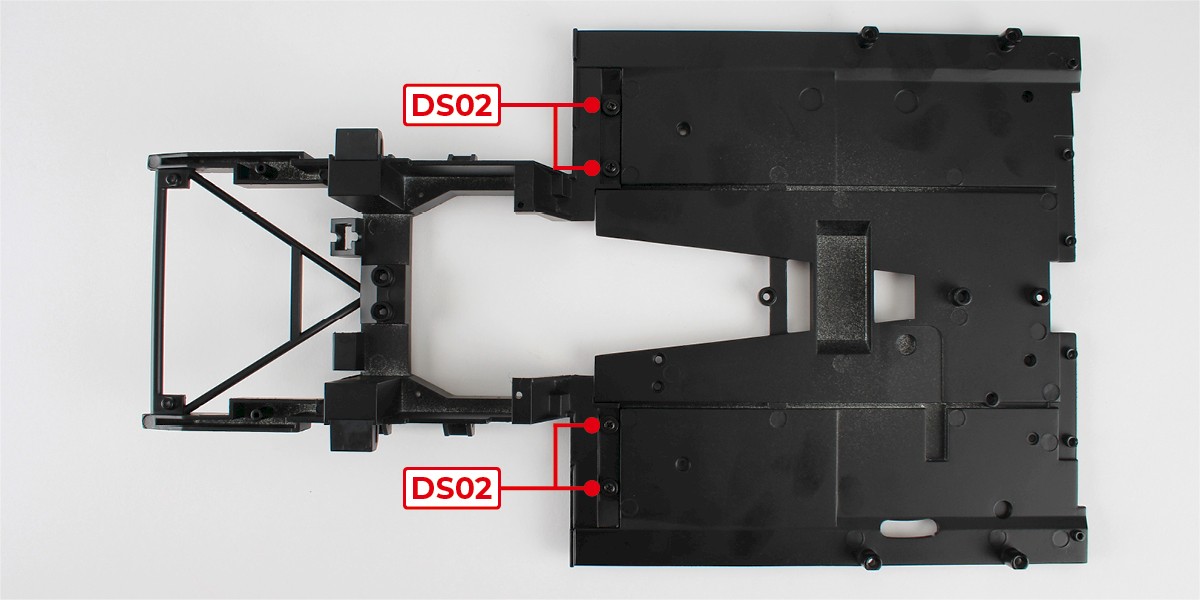

| 21-A Chassis middle |

| 5x DS02 screws |

STAGE COMPLETE

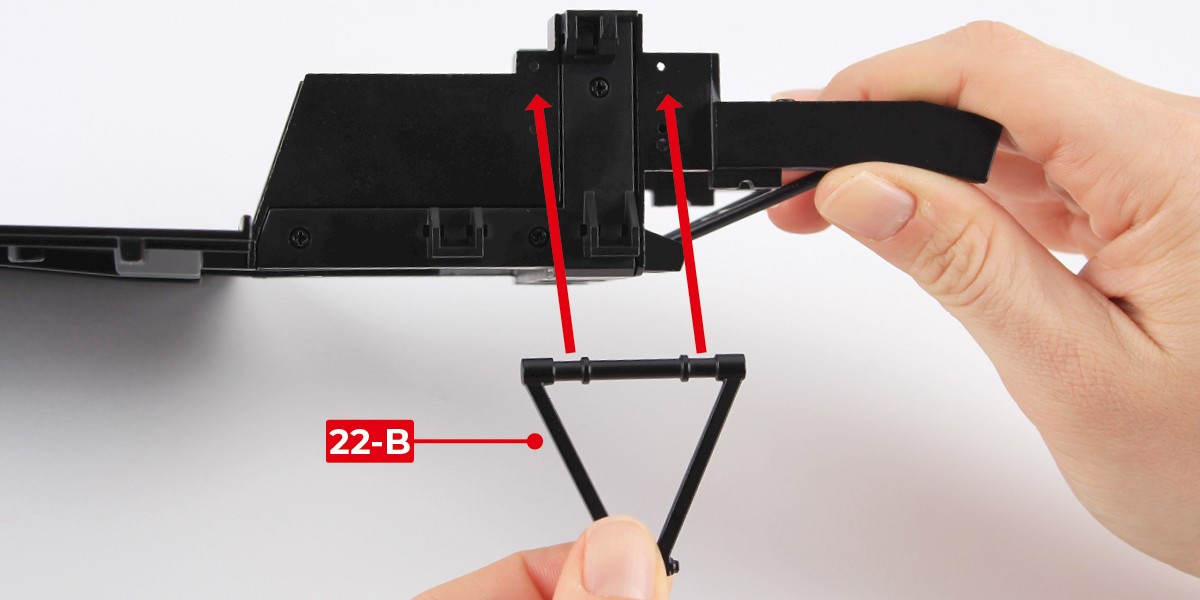

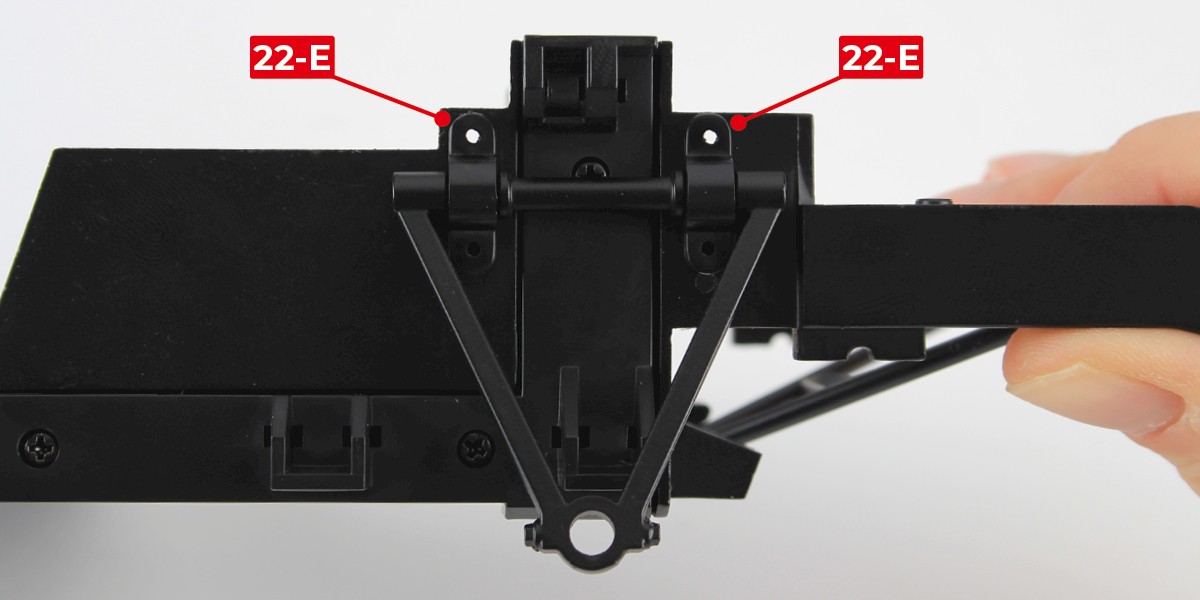

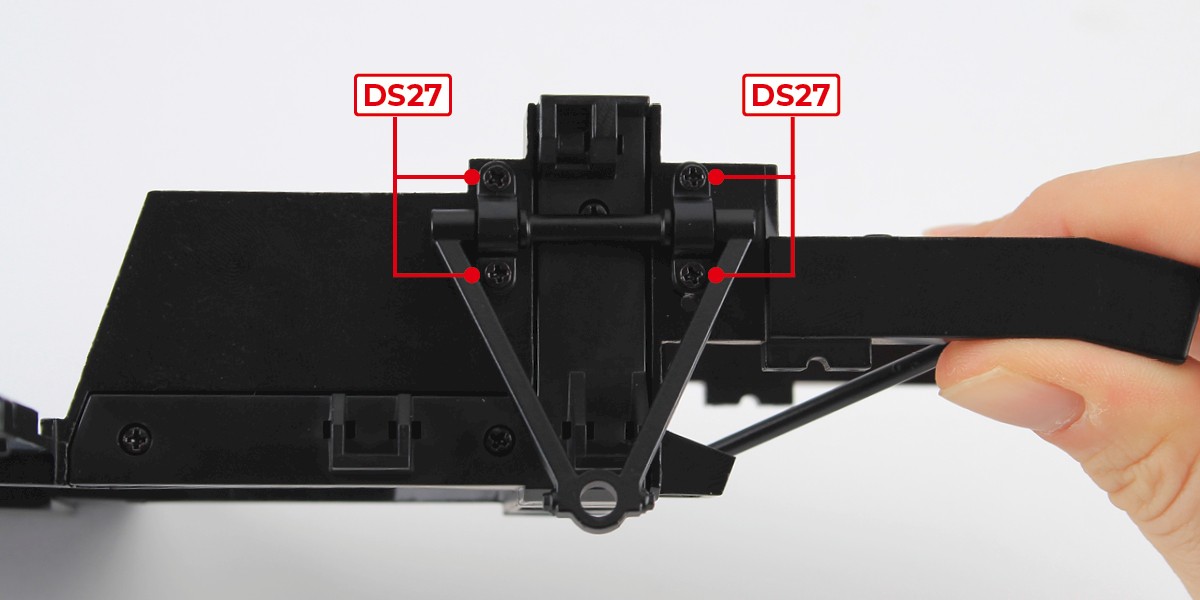

PARTS LIST

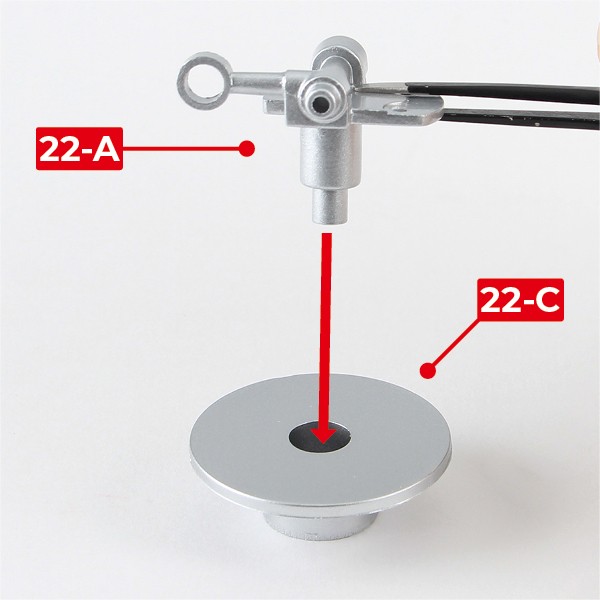

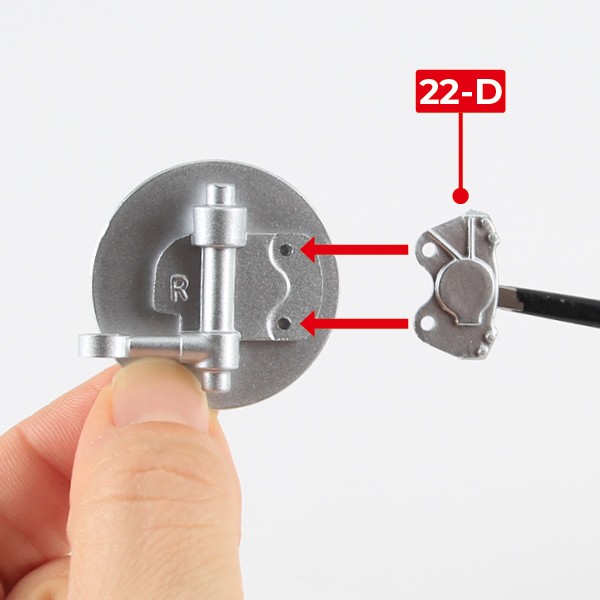

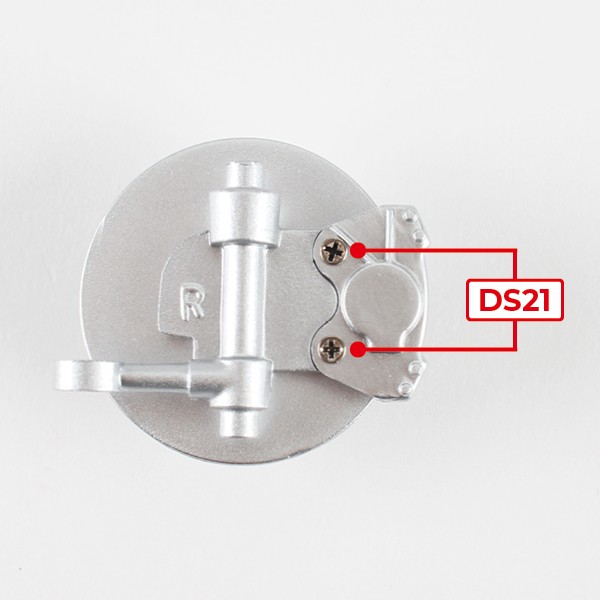

| 22-A Right wheel hub | 22-E Bracket x2 |

| 22-B Upper right control arm | 3x DS21 screws |

| 22-C Brake disc | 5x DS27 screws |

| 22-D Caliper |

STAGE COMPLETE

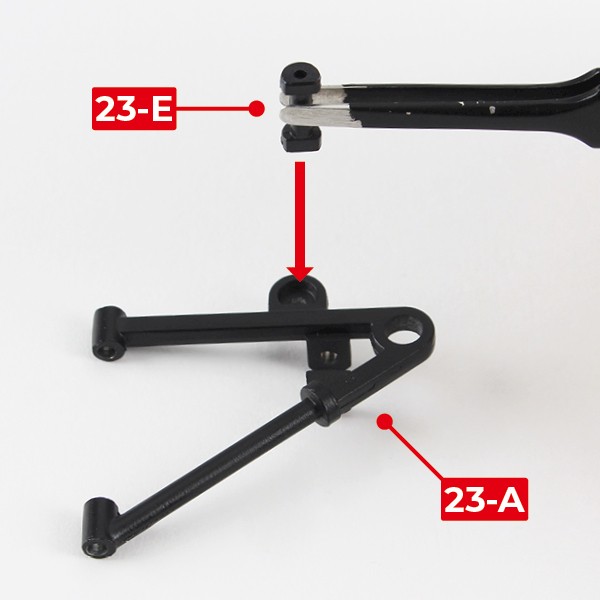

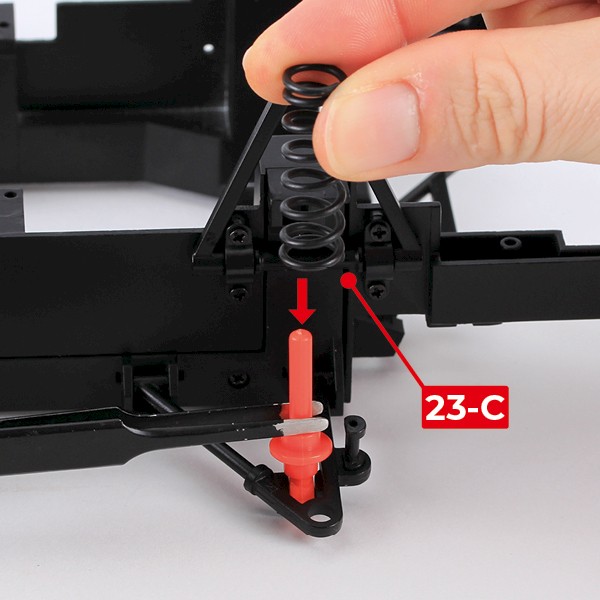

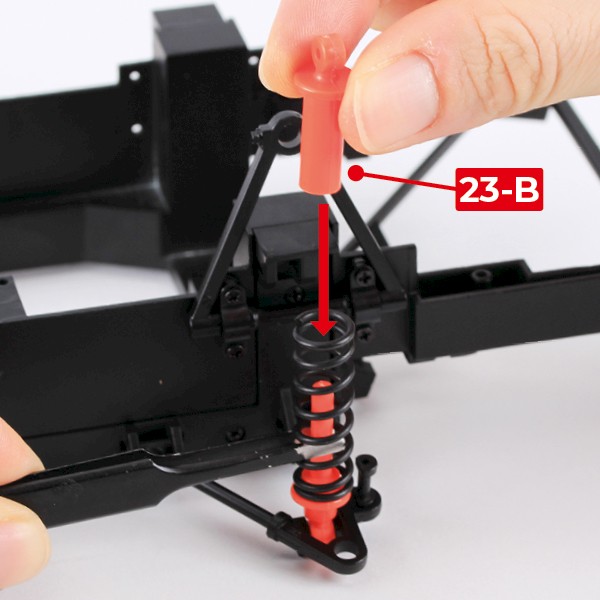

PARTS LIST

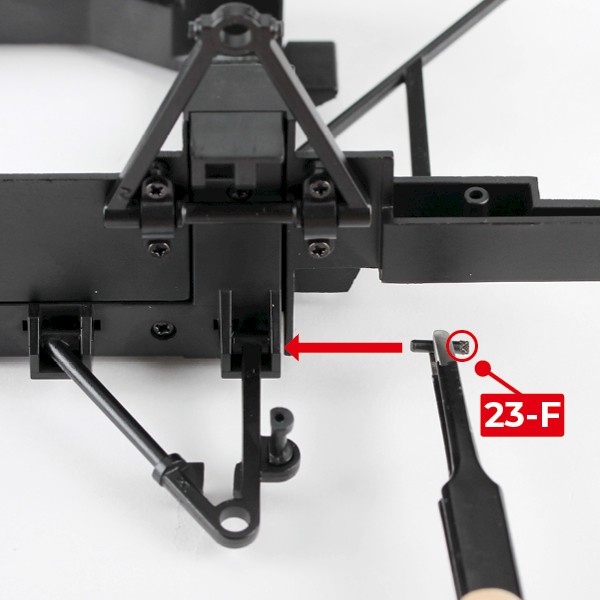

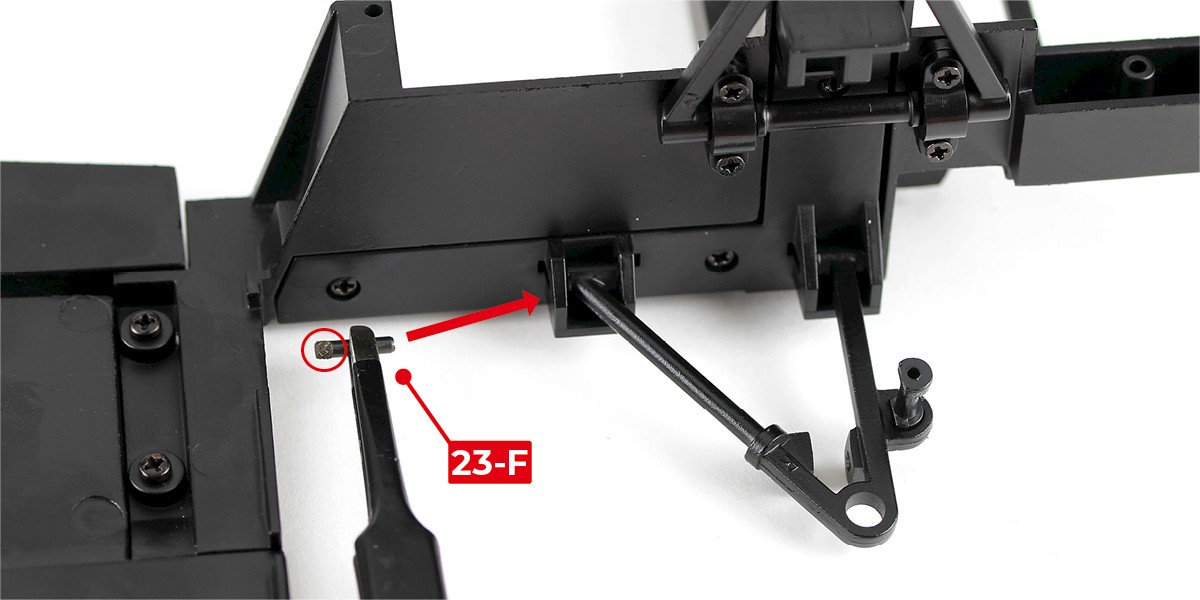

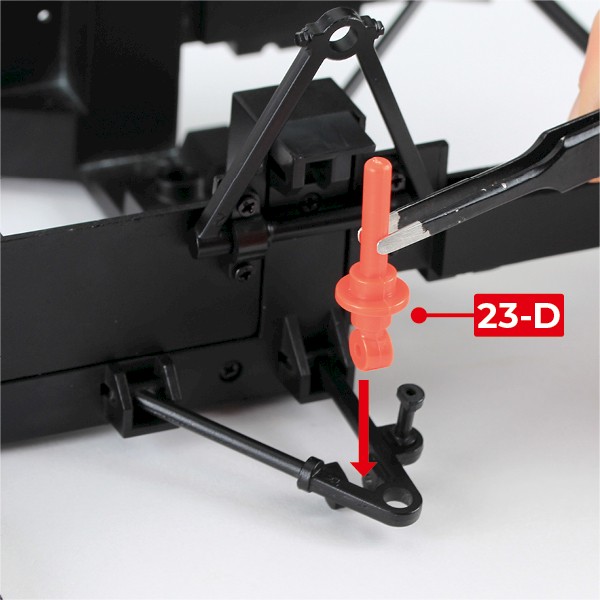

| 23-A Lower right control arm | 23-E Anti-roll bar connection |

| 23-B Shock absorber cylinder | 23-F Pin x5 |

| 23-C Spring | 3x DS24 screws |

| 23-D Shock absorber rod | 2x PS31 screws |

STAGE COMPLETE